19

ADJUSTMENTS

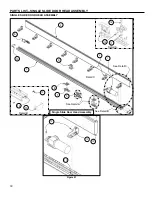

—MOTOR BRAKE

4. Inspect all photo eyes. If a photo eye appears

damaged, bent, or out of position, replace or

readjust the eye or mounting bracket as required.

5. Observe the indicator lights to verify that the

photo eye modules are aligned. The green light

indicates the photo eye transmitter module is

powered up. When the yellow light on the

receiver module is also lit, the emitter and

receiver modules are properly aligned.

MOTOR BRAKE ADJUSTMENT

1. Turn off the power to the door.

The disconnect must be in the OFF position

and properly locked and tagged before

performing the following procedure.

2. Loosen the retaining bolts securing the brake

dust cover to the motor assembly. Remove the

cover. (See Figure 43)

Figure 43

3. To adjust the brake, first securely tighten all

brake adjustment nuts. Then back off each nut

1/2 turn counterclockwise. (See Figure 44)

All nuts must be equally adjusted or the

brake mechanism will wear unevenly.

4. Attach the dust cover and tighten all retaining

bolts.

5. Turn on the power to the door.

6. With all seals adjusted and secured, cycle the

door open and closed several times to test the

seals. Then fully close the door and verify that

the floor sweep seals around the door panel

have remained in place and seal properly against

the floor. Make any necessary adjustments.

Figure 44

CHAIN RELEASE ASSEMBLY ALIGNMENT AND

ADJUSTMENT

The chain release assembly will occasionally need

adjustment as the chain drive and panels are normal

wear items. It generally will require alignment and

adjustment any time the door panel is adjusted or the

drive chain system needs servicing. The Assembly

must be properly aligned with the chain for proper

operation or wear, damage, and/or other

performance problems will occur.

1. Move the door panel(s) to the fully closed

position.

2. Turn off power to door.

The disconnect must be in the OFF position

and properly locked and tagged before

performing the following procedure.

3. Gain access to head assembly and drive chain.

4. After the door panel(s) has been properly

aligned, leveled, elevated, and secured to the

head assembly via the swivel hangers, the drive

chain properly tightened, and the bulb seal

compression properly set, the chain release

mechanism assembly can be aligned with the

drive chain between the idler sprockets and the

drive. Loosen the fasteners securing the chain

glide bracket and the manual chain release cable

in this assembly. Adjust the height of the bracket

so the chain glide is at the same height as the

chain and level (chain runs level and is not being

lifted or pulled down by it). (See Figure 45)

Dust Cover

Brake Adjustment

Nuts (Three Total)

Dust Cover Retaining

Bolts (Four Total)

Содержание Turbo-Slide

Страница 2: ......

Страница 8: ......

Страница 29: ...21 NOTES...

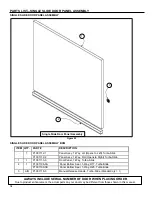

Страница 32: ...PARTS LIST BI PARTING DOOR ASSEMBLY 24 BI PARTING DOOR ASSEMBLY Figure 48 1 2 3 4 6 7 8 9 10 Bi Parting Door 5...