6

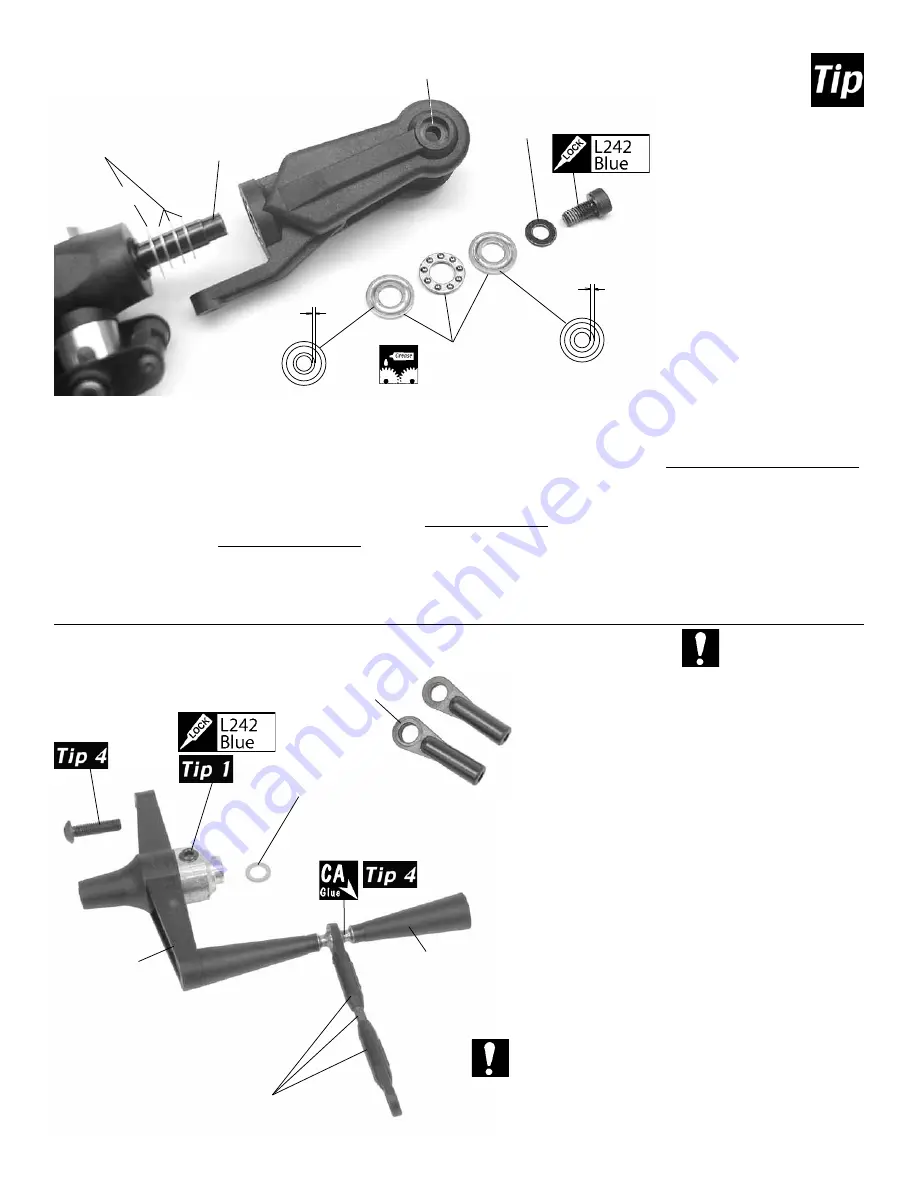

Remove one damper and press the feathering spindle to seat the ball near the center of the rotor hub. Reposition the rubber

damper in the rotor hub and slide one large shim against the damper followed by three regular stiffness shims and one blade

grip assembly onto the feathering spindle. The bell mixer and pitch arm of the blade grip is mounted on the leading edge

when as the head rotates clockwise. Install the M7x15 thrust bearing and lubricate the bearings with light grease. Looking at

the two steel races of the thrust bearing, note that the innermost surfaces have different widths because the inside diameters

are different. Slide the first larger diameter steel washer (

thin race, larger ID) followed by the greased ball race, followed by

the second steel washer (thick race, smaller ID). Remove any grease that may have transfered to the threads using a cotton

swab dipped in alcohol. Apply L242 Blue threadlock to the inside threads on the feathering spindle using a pin and install

the M5x10 socket cap screw with washer. Do not overtighten this bolt because it will flair the end of the spindle making

removal of the blade grip nearly impossible. Repeat for the other blade grip.

Step 7 Feathering Spindle & Blade Grip

#HW6182

Stiffness

Shims

#HW6180A

Feathering

Spindle

Large

#HW6180A M5x10

Socket Screw & M5

Flat Washer

thin

race

(inside)

larger ID

thick race

(outside)

smaller ID

#CNBB715T

M7x15 Thrust

Ball Bearing

Hobby Grease

Generally, grease

is needed for thrust

bearings and the tail

rotor gears. A light

Lithium or Silicon

grease should be

used, commonly

found at hobbyshops

for RC cars.

Step 8 Flybar Control Yoke

Pushrod A is already assembled but check that the length is

actually 47mm (center to center). As the pushrods are build

and installed they should be checked for tightness. Press

one ball link onto each double studded steel ball, making

sure that pressure is applied from the side of the ball link

with circle mark. While holding one flybar control arm, ap

-

ply a small amount of slow cyanoacrylate glue and thread

one end of the double studded steel ball into each standoff.

When it becomes difficult to turn with fingers, apply slow

CA to the threads and start screwing in the tapered control

arm stand-off on the other end of the ball.

M3x12 Button

Cap Screw

#HI3176C

Flybar Con-

trol Arm

#HW3176C Double

Studded Steel Ball

Pushrod A 47mm

(center to center)

#HI6145 Ball Link x 2

#HW6192 25mm Pushrod x 2

#CNLR1006

M4x6 Micro Washer

M4x5 Set

Screw

#HI3176C

Tapered

Standoff

Ball Link Direction

All ball links are molded to be installed in only one

direction. Look carefully at the hole for the ball,

one side is clean while the other side has a circular

mark, 1mm larger than the hole. The marked side

presses over the steel control balls.

Circle Mark

presses over

steel ball.

Round Recess

on Top

A correctly installed the ball link should rotate with

some resistance when the metal pushrod is rotated in

your fingers. If the ball link to too tight the preferred

solution is to purchase Century’s ball link sizing tool

[CN2055] to custom fit each ball link to its steel ball.