PACTware Multi-Input/Output Device Type Manager

2

0

1

8

-0

7

75

Section "Identification information":

■

Strategy:

Free value field, enter value to use for configuration or diagnostics as a code

key for sorting or summarizing diagnostic information.

■

Alert key:

Free value field, enter any value for sorting alarms or events that have been

generated. The value can contain the identification number of the plant unit. It helps to

identify the location (plant unit) of an event.

■

Description:

Free text field, enter any information to describe the device as a measuring

point in the application.

■

Message:

Free text field, enter any information to describe the device in the application or

plant.

■

Installation date:

Free text field, enter the installation date of the device in the plant.

Adjusting the Device Information

1. Use the different fields to enter the information you require for your process.

2. Click on

Apply

.

10.3.2

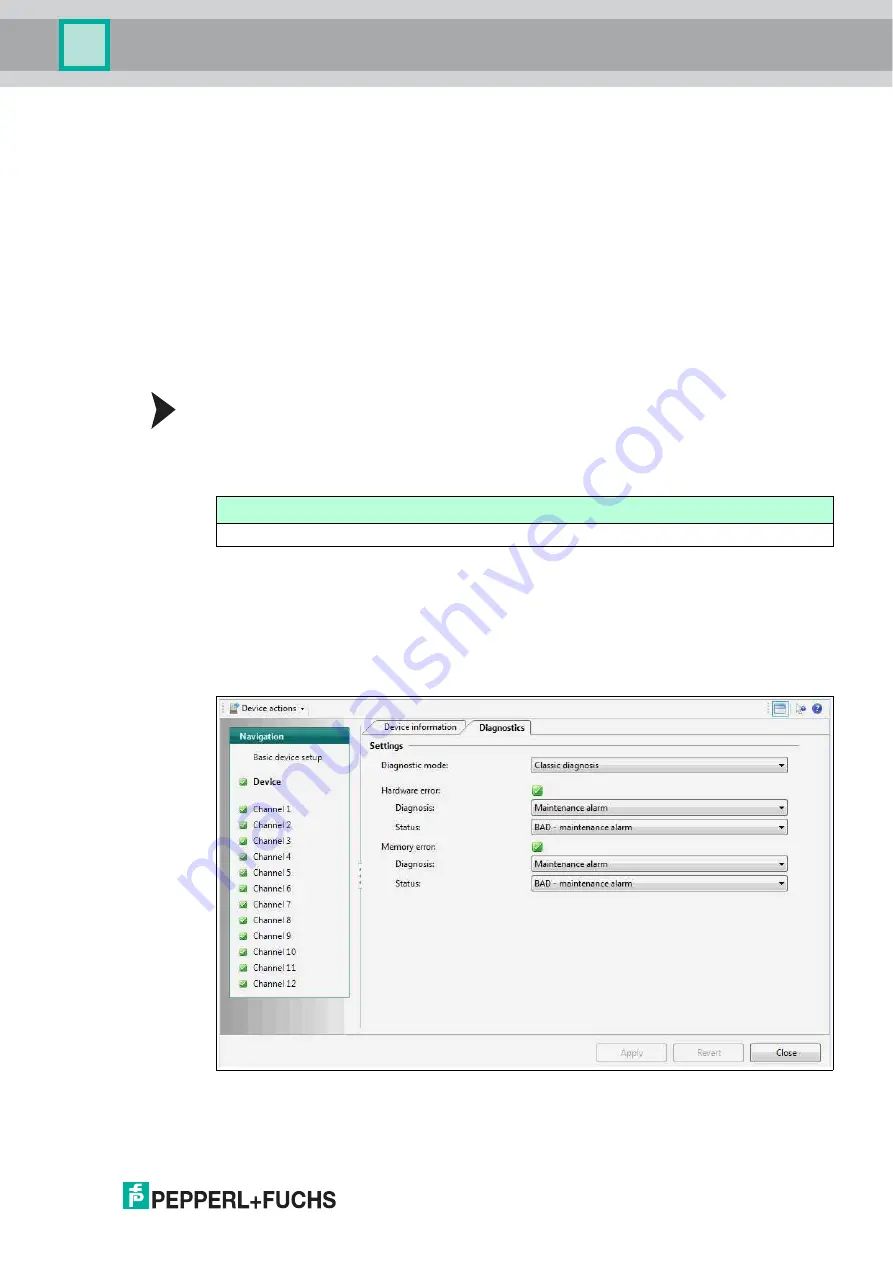

Device Tab "Diagnostics"

In the DTM, the tab "Diagnostics" enables you to configure the diagnostic behavior of the

device. The settings apply to all sensor input modes.

Figure 10.15

Device "Diagnostics" tab

More Information

For more information on the identification information, see chapter 3.3.