Operation

Version 1.0.5 - 2020-12-09

41

Translation of original instruction

TX4414

EN

T

X

4414

_GB

_4.

fm

4.11.3 Maintenance of chucks

A crucial prerequisite for fault-free functionality of a lathe chuck is regular and thorough lubrica-

tion of the sliding surfaces. This prevents the reduction of tensioning force and premature wear

and tear. Always observe the manufacturer's maintenance instructions when using replacement

lathe chucks.

Coolant squirts on the lathe chuck and removes the grease from the jaws. In order to maintain

the tensioning force and the long-term accuracy of the lathe chuck, the lathe chuck must be

lubricated regularly. Insufficient lubrication will result in malfunctions with significantly reduced

tensioning force, which affects the accuracy and causes excessive wear and seizing.

Lubricate the installed lathe chuck at least once per week. The used lubricant should be of high

quality and provided for high pressure bearing surfaces. The lubricant should withstand the

coolant and other chemicals.

Clamping jaws and jaw mounting screws are wear and tear parts. The service life is limited. We

therefore recommend having them inspected at regular intervals by a specialist (e.g. inspection

for cracks using a dye penetration process or magnet powder test (fluxing), eddy current test-

ing, ultrasound testing) and replace if necessary.

4.12

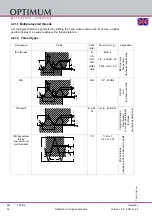

Clamping a workpiece into the lathe chuck

When the workpiece is being clamped unprofessionally, there is a risk of injury as the work-

piece may fly off or the jaws may break. The following examples do not show all possible situa-

tions of danger.

Incorrect

Correct

Clamping length too short,

overhang too long.

Additional support over

center or rest.

Clamping diameter too

large.

Larger

lathe necessary.

Workpiece is too heavy

and clamping jaw is too

short.

Support over center,

enlarged jaw.

Enlarged jaws are not

available for this three-jaw

chuck.

Possibly use larger lathe.

Содержание OPTIturn 3432420

Страница 1: ...GB Operating Manual Version 1 0 5 Lathe Part no 3432420...

Страница 123: ...Version 1 0 5 2020 12 09 123 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm R Schaltplan Wiring diagram...

Страница 124: ...Version 1 0 5 2020 12 09 124 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm S Schaltplan Wiring diagram...

Страница 125: ...Version 1 0 5 2020 12 09 125 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm T Schaltplan Wiring diagram...

Страница 138: ...Version 1 0 5 2020 12 09 138 Translation of original instructions TX4414 EN TX4414_GBSIX fm...