Rotary chuck - K11-200 ISO 702-2

Version 1.0.5 - 2020-12-09

90

Originalbetriebsanleitung

3442762

│

3442763

│

3442764

GB

K11-

200_I

SO

-702

-2_3

4427

62_3

44276

3_43

3276

4_GB

.f

m

The centrifugal torque of the base jaws M

cGB

can be found in the data of the lathe chuck.

The centrifugal torque of the top jaws M

cAB

is calculated.

The lathe chuck K11-200 has no base jaws and no top jaws.

Example:

The centre of gravity radius r

s

of the jaw = 0.0632 m (jaw flush with the outer diameter of

the chuck)

Weight of a jaw = 0.622kg

Centrifugal moment for one jaw

The lathe chuck has 3 jaws.

Calculation of the total centrifugal force at a rotational speed of 3000 rpm

The total possible clamping force of the chuck at a standstill is

∑

s

31 kN at a tightening torque

of 250Nm with the lathe chuck key.

An effective clamping forceF

sp

of 19.4 kN remains at the chuck.

see

"Clamping force-speed diagram - Lathe chuck K11-200“ on page 88

see

"Basic safety instructions“ on page 86

WARNING!

The greater distance above the chuck surface that clamping occurs, the lower the

clamping force will be.

7.8

Notes on instruction of operating personnel

We recommend that the business operating our manual chucks makes the operating instruc-

tions in particular the section "Safety" available to all persons being in charge of operation,

maintenance and repair, with the intention ofacquiring specialised knowledge. We further rec-

ommend that the business operator issues internal "operating instructions" which take into

account the known qualifications of the operating personnel.

The business operator must guarantee that suitable measures in organisation and instruction

are taken to ensure that the appropriate safety rules and regulations are complied with by the

persons entrusted with operation, maintenance and repair of the manual chuck.

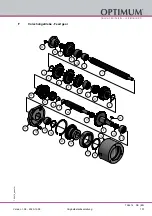

7.9

Scope of delivery

Note: Soft, non-stepped jaws are only available as an option.

1 manual clamping chuck (complete) with camlock bolt for direct fixing of the chuck on a

lathe as per DIN ISO 702-2 , size depending on the spindle size.

1 set of internal clamping jaws, centric clamping

M

cAB

= m

AB

·

r

sAB

[ kgm ]

M

c

= 0.622 kg

·

0.0632m = 0.0393 kgm

= 0.0632 kgm

·

3 = 0.11793 kgm

F

c

=

∑

(m

b

·

r

s

)

·

π

·

n

30

(

)

2

=

∑

M

c

·

π

·

n

30

(

)

2

[N]

( )

=

0.11793 kgm

·

3.14

·

3000

30

2

= 11627 N = 11.6 kN

F

sp

=

∑

s

- F

c

=

31 kN - 11.6 kN =

19.4 kN

Содержание OPTIturn 3432420

Страница 1: ...GB Operating Manual Version 1 0 5 Lathe Part no 3432420...

Страница 123: ...Version 1 0 5 2020 12 09 123 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm R Schaltplan Wiring diagram...

Страница 124: ...Version 1 0 5 2020 12 09 124 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm S Schaltplan Wiring diagram...

Страница 125: ...Version 1 0 5 2020 12 09 125 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm T Schaltplan Wiring diagram...

Страница 138: ...Version 1 0 5 2020 12 09 138 Translation of original instructions TX4414 EN TX4414_GBSIX fm...