Rotary chuck - K11-200 ISO 702-2

Version 1.0.5 - 2020-12-09

91

Originalbetriebsanleitung

3442762

│

3442763

│

3442764

GB

K11-

200_I

SO

-702

-2_3

4427

62_3

44276

3_43

3276

4_GB

.f

m

1 set of external clamping jaws, centric clamping

1 clamping key without ejector

1 Operating manual

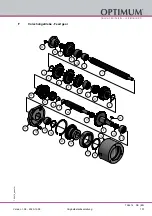

7.10

Assembly

7.11

Assembly of the manual chuck

7.11.1 Handling before mounting

Actuate the chuck before assembly on the lathe. Turn the spindle to the left by means of the

clamping key until it stops.

The numbered jaws have to be pushed into the correspondingly numbered guidance (jaw 1 into

guidance 1 etc.)

Finally turn the spindle several times to the right and to the left until it bottoms out.

7.11.2 Preparing the chuck attachment

Check the head of the machine spindle or the ready-machined intermediate flange on true-run-

ning and face play. The contact face has to be chamfered and clean at the bores. Remove pos-

sible damages at the mounting faces of the spindle head. In case of flange spindles, the contact

face has to be checked with a straight edge. For fastening with an intermediate flange please

note that the flange needs full contact with the chuck body. The flange must be supported by

the whole face.

7.11.3 Mounting of the manual chuck

Thoroughly clean the centering and the bearing surfaces of both parts and lubrify them with oil

before placing the chuck onto the spindle head. When the chuck is slightly pressed, there

should be a noticeable play and between the faces there should be a gap of max. 0.02 mm

(feeler gauge).

7.12

Lubricating and cleaning the lathe chuck

ATTENTION!

Do not use compressed air to remove dust and foreign substances from the lathe chuck.

Coolant squirts on the lathe chuck and removes the grease from the master jaws. In order to

maintain the tensioning force and the long-term accuracy of the lathe chuck, the lathe chuck

must be lubricated regularly. Insufficient lubrication will result in malfunctions at reduced ten-

sioning force, which affects the accuracy and causes excessive wear and seizing.

Depending on the chuck type and operating state, the tensioning force of a lathe chuck can

decrease by up to 50 percent of the nominal tensioning force.

A presumably securely clamped workpiece can then fall out of the chuck during processing.

Oil the chuck regularly at the oiler. Use additional an lubricant on the toothing of the clamping

jaws, which is of high quality and for high pressure bearing surfaces. The lubricant should with-

stand the coolant and other chemicals.

Содержание OPTIturn 3432420

Страница 1: ...GB Operating Manual Version 1 0 5 Lathe Part no 3432420...

Страница 123: ...Version 1 0 5 2020 12 09 123 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm R Schaltplan Wiring diagram...

Страница 124: ...Version 1 0 5 2020 12 09 124 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm S Schaltplan Wiring diagram...

Страница 125: ...Version 1 0 5 2020 12 09 125 Originalbetriebsanleitung TX4414 DE EN TX4414_parts fm T Schaltplan Wiring diagram...

Страница 138: ...Version 1 0 5 2020 12 09 138 Translation of original instructions TX4414 EN TX4414_GBSIX fm...