-

43

-

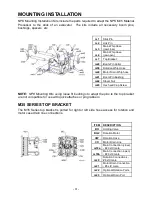

GENERAL MAINTENANCE

LUBRICATION POINTS

M35

GR1

CYLINDER ROD PINS One lubrication point per

cylinder located at the jaw

attachment end.

10 strokes from a grease

gun every 4 hours.

GR3

JAW PIVOT PIN

One lubrication point on each

end of pin

("S", early "K" and

"G" jaws)

. Two lubrication

points on one end, one

lubrication point on the other

end

(later "K" jaws)

.

15 strokes from a grease

gun per fitting every 4

hours.

GR4

SLEWING

RING/PINION TEETH

Two lubrication points 180°

apart.

5 strokes from a grease

gun per fitting per shift.

GR5

MOTOR PINION

One lubrication point on each

side of the hydraulic motor

located on the top bracket.

5 strokes from a grease

gun per fitting once per

shift.

GR6

CYLINDER BASE END

PINS

One lubrication point located at

the main frame attachment end.

10 strokes from a grease

gun every 4 hours.

Содержание M35G

Страница 13: ... 13 SERIAL NUMBER LOCATION M35 ...

Страница 115: ... 115 WARRANTY STATEMENTS ...

Страница 116: ... 116 WARRANTY STATEMENTS ...

Страница 118: ... Copyright 2018 NPK Construction Equipment Inc www npkce com M000 9601B M35 Material Processor Instruction Manual 10 18 ...