gas leakage. Seal all leaks before placing the

humidifier in operation.

WARNING:

Never use an open flame to check for

gas leaks. If a leak does exist, a fire or explosion

could occur, resulting in damage, injury or death.

The appliance must be isolated from the gas

supply piping system by closing its individual manual

shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or

greater than 14” w.c. (3.5 kPa).

Dissipate test pressure from the gas supply line

before re-opening the manual shut off valve to the

appliance.

NOTES:

1.

Failure to follow this procedure may damage

the gas valve. Over pressured gas valves are

not covered by warranty.

2.

DO NOT use Teflon tape on gas line pipe

threads. A flexible sealant suitable for use

with Natural Gas and Propane Gas is

recommended.

3.

Plan gas supply piping so it will not interfere

with removal of gas valves or blower

assemblies and front or side service doors.

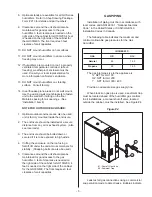

The gas valve is provided with pressure taps to

measure gas pressure upstream and downstream,

(manifold pressure). The minimum gas pressure

shown is for the purpose of input adjustment.

A 1/8" NPT plugged tapping, accessible for test

gage connection, must be installed immediately

upstream of the gas supply connection to the

appliance.

NOTE FOR OUTDOOR ENCLOSURE:

Gas lines

should be routed through the bottom of the enclosure.

NOTE FOR DIRECT VENT UNITS:

The

combustion supply air opening is not required to the

room where the appliance is installed since the

combustion air will be provided through the inlet air

duct (see installation notes below). Ventilation is

required for cooling of the electronic components

AIR MANIFOLD/CONNECTOR HOSE

INSTALLATION FOR DIRECT VENT

All direct vent units are shipped with the air

manifold and connector hoses packaged separately.

The connector hoses and air manifold must be

installed by a qualified installer prior to commissioning

the unit.

Procedure:

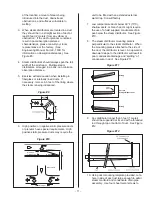

1.

Apply a ring of silicone around the outside of

each of the blower adapter connector.

2.

Mount a flexible connector hose over the hose

connection on each blower adapter and

secure using a gear clamp provided with the

unit. Care should be taken not to kink or

damage the flexible hose. Refer to Figure #5.

3.

Carefully bend the flexible hose(s) to give the

“S” shape as shown in the diagram.

4.

Mount the air intake manifold to the cabinet

base using the mounting bracket located on

the bottom of the air manifold (refer to Figure

6). DO NOT PUNCTURE OR ADD ANY

HOLES TO THE AIR MANIFOLD.

5.

Apply a ring of silicone to the outside of each

hose connection on the air manifold.

6.

Mount the corresponding flexible connector

hose over each hose connection on the air

manifold and secure using a gear clamp

provided with the unit.

- 6 -

Figure #5

Figure #6

Содержание GH 100

Страница 43: ... 39 ...