- 27 -

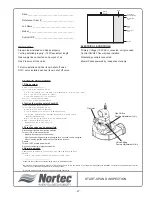

START-UP AND INSPECTION

Date:_____________________________________

Reference Order #:__________________________

Job Name:_________________________________

Model:____________________________________

System ID #:_______________________________

STARTUP PROCEDURE

1.Filling system

Manually close fas supply to unit

Turn unit ON at the main power switch.

Unit will fill automatically until low water float is reached and trial for ignition will begin

After 3 tries, the ignition module will lockout

Unit will shut down on fault (ignition lockout)

Wait until fill sequence is completed

Turn unit OFF at the main power switch

2.Testing the ignition safety Shut-OFF

Manually close gas supply to the unit

Turn unit ON at the main power switch

Blower will pre-purge for 30 seconds .

On multiple blower units, wait until all blowers have cycle

.

The igniter will glow and after 7 seconds the gas valve will energize for 4

seconds, the de-energize...

After 3 tries, the ignition module will go into a safety lockout .

Manually re-open Gas Supply to the unit.

. No gas should flow to the main burner

.

. End of test

.

3.Purge fas valves and gas manifold

Disconnect all igniters from ignition modules

Turn unit ON at main power switch

… Blower will pre-purge for 30 seconds...

… After 7 seconds the gas valve will energize for 4 seconds, the de-energize...

… After 3 tries the ignition module will go into safety lockout...

Repeat

Turn unit OFF at main power switch

Re-connect all igniters to ignition modules

4.Normal operation

Reset system by momentarily shutting OFF main power switch and switching

back ON

Igniter will start to heat up and normal operation cycle will occur

_________________________________

1

Steam line use 3ft above unit before sloping min 10º to distribution system.

2

BH Venting in stainless steel only (class III for GH 100 and class IV for GH 200 & 400). Co-venting with other appliance is prohibited. Vent must be same diameter as the vent

connector. 100-ft equivalent length maximum including elbows.

3

Drain lines must be kept as short as possible and slopped downwards.

Drain

Gas Input

Line

Water Input

Line

Power And

Control Wiring

Steam

Outlet

Vent

DWC

Line

MECHANICAL

ELECTRICAL & CONTROLS

Steam Lines installed and sloped properly

1

Primary Voltage (120 VAC) connected

,

unit grounded

Venting installed properly

2

<100ft equivalent length

Control ON/OFF Security loop installed

Gas supply line connected and purged of air

Modulating controls connected

Gas Pressure at Gas Valve

Blower Packs powered by independent supply

Fill valve installed and has its own shut off valve

DWC valve installed and has its own shut off valve

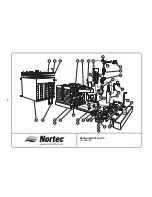

Gas Inlet

Gas Orifice

Factory Adjustment Only

Valve Setting

Factory Adjustment Only

Содержание GH 100

Страница 43: ... 39 ...