9.

If steam line is routed below steam distributor

or if the steam distributor is lower than the

humidifier, a condensate trap “tee” will be

required to remove water at this low point.

Run condensate from trap to nearest drain

lower than the distributor. See Figure #24.

10.

Do not run steam line more than 1 foot per

lb/hr output. Example, 10 lbs/hr should not

have a steam run longer than 10 feet. If long

runs are unavoidable, the humidifier should be

sized larger to compensate for condensate

losses and insulated copper should definitely

be used.

NOTE FOR OUTDOOR ENCLOSURE:

It is

recommended to insulate steam lines between

the enclosure and the building or air handling

unit specifically if freezing conditions may

occur.

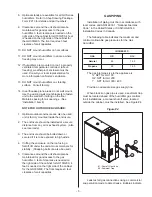

WATER TRAP

1.

The GH Series humidifier produces steam at

atmospheric pressure. Pressure head must

develop to push steam through supply line and

into air duct.

2.

Combined resistance of duct positive static

pressure and steam line resistance creates a

small pressure head in water tank. Total

amount of positive static pressure head is

reflected directly by water column differential

that develops in the built in water trap.

3.

The built in water trap allows a maximum of

4.5" W.C. pressure before tank water escapes

through drain. This pressure should not be

exceeded.

4.

Static pressure is usually higher when

distributor's steam outlets are faced upstream

in a duct.

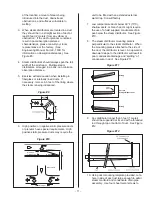

CONDENSATE RETURN LINES FOR STEAM

DISTRIBUTORS

1.

Nortec steam distributors and blower packs

have built-in connections for draining off

condensate. These condensate lines must be

connected to the nearest floor drain or to a

condensate pump (available from NORTEC).

A flexible condensate hose, (available from

NORTEC), may be used for short condensate

runs.

2.

Always incorporate a trap in routing of

individual condensate return lines.

Condensate that accumulates in trap will

prevent possibility of steam escaping. Depth

of trap must exceed duct static pressure in

inches of water column. See Figure #25.

3.

Ensure the trap is 3’ minimum under the

steam distributor and have the trap as close to

the floor drain as possible.

4.

Provide a “U” trap in condensate line even

when distributor is located in return air

plenum. It stops a suction action from

impeding condensate flow with duct pressures

below atmosphere.

- 15 -

Condensate Trap

Depth Of Trap "Y"

Must Be 2" More Than

Duct Static Pressure

min 3’

Figure #25

Figure #24

Содержание GH 100

Страница 43: ... 39 ...