Reviews:

No comments

Related manuals for Dryair DK

1000

Brand: Lasko Pages: 2

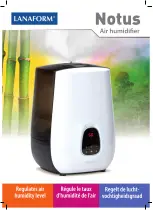

Notus

Brand: Lanaform Pages: 88

NXC 0020

Brand: NANO Pages: 64

HL-OS-10

Brand: Haus & Luft Pages: 44

ED 1300 W

Brand: omi Pages: 94

L-493B

Brand: Livart Pages: 6

CZHD91

Brand: Comfort Zone Pages: 6

ElectroVap KIT MC 10

Brand: Devatec Pages: 36

AOS?W2255

Brand: Air-O-Swiss Pages: 96

DDR4510E

Brand: Danby Pages: 5

DDR201

Brand: Danby Pages: 12

DDR2510E

Brand: Danby Pages: 16

DDR050BGWDB

Brand: Danby Pages: 28

DDR030EACWDB

Brand: Danby Pages: 28

DDR050BJPWDB-ME

Brand: Danby Pages: 32

DDR020BJWDB-ME

Brand: Danby Pages: 32

DDR070BBCBDB

Brand: Danby Pages: 40

60-1

Brand: Skuttle Indoor Air Quality Products Pages: 40