27

Information, parameters and controls on the overview screen will vary depending on the options of

each oven.

1) The temperature control for each heat channel will display the set point (SP) and the actual

temperature process value (PV). Clicking on the temperature channel (SP) box, and then

entering a new set point will change the set point. The set points (SP) can be edited by the

user in Operate mode. The process values (PV) are being constantly monitored and

updated in Operate mode.

2) A description box located on the top of the screen displays the currently selected channel.

3) The conveyor speed can be changed by clicking on the conveyor (SP) box, and inserting a

speed in units of distance / time.

4) The signal light tower animation tracks the condition of the oven status. A red light indicates

that the oven is currently in an alarm state. A yellow light indicates that there is a warning

state present or the oven is in its startup sequence. The green light indicates that the oven is

in process ready state and able to accept boards.

5) Clicking on the (SP) box and inserting a new width in units of length can change the rail

edge width (for computer controlled edge hold systems only). The actual position is

displayed in the (PV) box.

6) The cooling fan speed can be adjusted by entering a number between 0 and 100% (if

equipped). For oven with heated cool zone cool fan speed is in between 65 and 100%.

7) Board tracking is monitored through the oven by displaying animation of the board as it

passes under the incoming board sensor (if equipped).

8) The supply of nitrogen to the machine can be turned on or off by clicking on the toggle

switch labeled ‘nitrogen’ on the overview screen.

9) The board drop option will allow the detection of a board falling off the edge hold conveyor

during the cure process and to establish a warning signal so that the operator can take

corrective action.

10) The board count option allows the computer to display a count of the number of boards

processed by the oven since a particular recipe has been loaded. As a board enters the

oven, it activates a sensor at the entrance, counting a board “in." As the board leaves the

oven it activates a sensor at the exit of the oven, counting a board “processed". This feature

may be used to count the number of boards processed.

11) The Center Board Support Up/Down button will allow vertical movement of CBS (if

equipped).

12) Computer control CBS (center board support) rail option (if equipped) will allow horizontal

rail adjustment by just entering the required rail width distance.

C. Selecting Screens and Functions

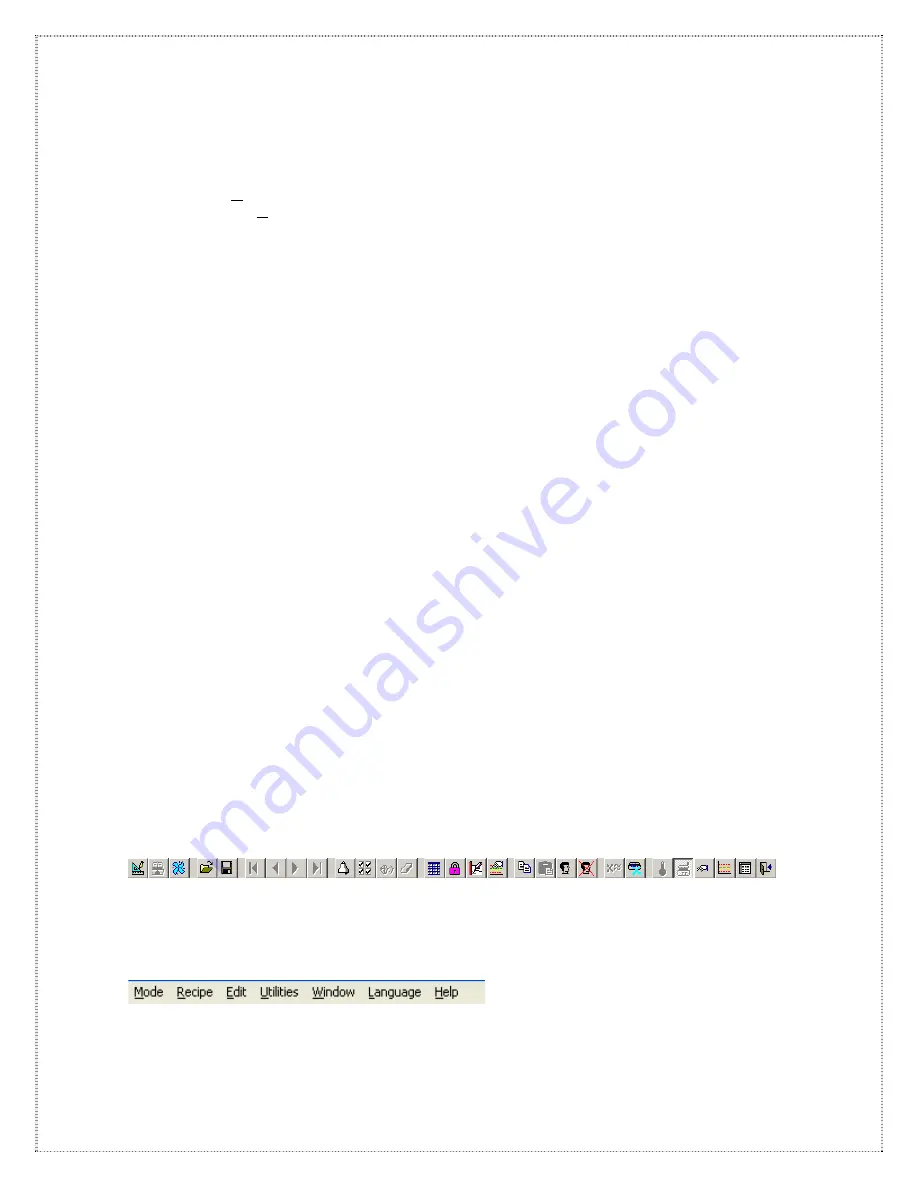

The main toolbar (

See

Figure 5

) depicts icons for different screens and function buttons. By clicking

on an icon screens can be displayed or the function button can be activated. By moving the mouse

arrow over an icon without clicking the mouse button a functional description of the chosen icon will

be displayed.

Figure 5

When clicking on the menu bar a pull down menu will be displayed also depicting the icons and their

related functions (

See

Figure 6A through 6G

).

Figure 6A

Содержание TCM-2200

Страница 5: ...1 Introduction ...

Страница 6: ...2 ...

Страница 18: ...14 ...

Страница 19: ...15 Facility Installation ...

Страница 20: ...16 ...

Страница 26: ...22 ...

Страница 27: ...23 Operating System Software Guide ...

Страница 28: ...24 ...

Страница 55: ...51 ...

Страница 56: ...52 ...

Страница 57: ...53 ...

Страница 58: ...54 ...

Страница 64: ...60 ...

Страница 65: ...61 Standard and Optional Equipment Operating Guide ...

Страница 66: ...62 ...

Страница 71: ...67 Troubleshooting Guide HC1 X or HC2 controller ...

Страница 72: ...68 ...

Страница 74: ...70 ...

Страница 95: ...91 Figure 12 ...

Страница 107: ...103 Maintenance Procedure ...

Страница 108: ...104 ...

Страница 110: ...106 ...