Installation Guide

|

Comfort Pack T Series

with up to

95% Gas Heat

25

1.

Adjust to the highest achievable temperature rise within the rise

and static pressure ranges specified on the rating plate.

2.

Make sure there are no leaks of outside air into the return air

system.

3.

Keep the outside louver grille as free as possible of any ice that

may form and obstruct the flue outlet.

THE GAS BURNER IN THIS GAS-FIRED

EQUIPMENT IS DESIGNED AND EQUIPPED TO

PROVIDE SAFE AND COMPLETE COMBUSTION.

HOWEVER, IF THE INSTALLATION DOES

NOT PERMIT THE BURNER TO RECEIVE

THE PROPER SUPPLY OF COMBUSTION

AIR, COMPLETE COMBUSTION MAY NOT

OCCUR. THE RESULT IS INCOMPLETE

COMBUSTION THAT PRODUCES CARBON

MONOXIDE, A POISONOUS GAS THAT

CAN CAUSE DEATH. SAFE OPERATION OF

DIRECT-FIRED GAS BURNING EQUIPMENT

REQUIRES A PROPERLY OPERATING VENT

SYSTEM THAT VENTS ALL FLUE PRODUCTS

TO THE OUTSIDE ATMOSPHERE. FAILURE

TO PROVIDE VENTING WILL RESULT IN A

HEALTH HAZARD WHICH COULD CAUSE

SERIOUS PERSONAL INJURY OR DEATH.

ALWAYS COMPLY WITH THE COMBUSTION

AIR REQUIREMENTS IN THE INSTALLATION

CODES. COMBUSTION AIR AT THE BURNER

SHOULD BE REGULATED ONLY BY

MANUFACTURER-PROVIDED EQUIPMENT.

NEVER RESTRICT OR OTHERWISE ALTER

THE SUPPLY OF COMBUSTION AIR TO ANY

HEATER.

!

DANGER

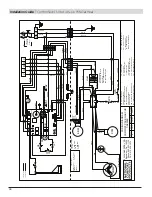

Figure 3: Gas Control

Maintenance and Service

The 20" x 25" x 1" filter on the cooling chassis must be maintained

regularly to assure that the unit provides optimal performance and

energy efficiency. The intervals between replacing depends entirely

on the cleanliness of the return air to the unit and the time that the

indoor blower operates. The air filter is accessible by removing the

lower access panel. The filter should be inspected and replaced as

needed and is not washable. Substituting the air filter with media

other than the type provided with the unit is not recommended,

since other materials may cause additional static pressure, which

could reduce the air delivery of the unit.

The unit should never be

operated without the air filter and access panels in place

.

Cooling Chassis

The cooling chassis contains all items related to the cooling

functions of the unit, and also contains the indoor blower and

motor for the heating function. For extensive servicing, qualified

personnel may choose to remove the cooling chassis from the unit

and take it to a work area. Spare chassis are recommended so that

extensive servicing can be performed outside the living space. This

will prevent introducing dirt or doing damage in the living area, and

could help to eliminate significant disruption of the air conditioning

and heating functions in the living areas.

The indoor blower motor and the outdoor fan motor have

permanently lubricated bearings and do not require routine

service. The refrigeration system is sealed and factory charged

with R-410A so that routine maintenance is not required. The

electrical controls do not require routine service. Cleaning of the

outdoor coil, indoor coil, drain pan, and inside the bottom of the

chassis are recommended at least once a year, and more often if

the equipment is operated in a dusty or hostile environment. The

outdoor coil is an aluminum microchannel condensing coil with

an anti-corrosion coating that requires specific precaution when

cleaning. It is recommended to rinse the coil using a low pressure

hose (less than 70 psi) to prevent buildup of dirt and debris.

Rinse from the outside of the coil in, making sure to protect the

condenser motor from water damage during the cleaning process.

Leaves, twigs, and other large debris should be removed with

Содержание Comfort Pack CP9 T Series

Страница 2: ...2...