Installation Guide

|

Comfort Pack T Series

with up to

95% Gas Heat

6

IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE

OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY

OR LOSS OF LIFE.

Do

NOT

store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS:

•

Do

NOT

try to light any appliance.

•

Do

NOT

touch any electrical switch; do not use any

phone in your building.

•

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

•

If you cannot reach your gas supplier, call the fire

department.

Installation and service

must

be performed by a

qualified installer, service agency or the gas supplier.

!

WARNING

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

FURNACE MUST BE REPLACED, IT MUST BE REPLACED

WITH WIRING MATERIAL HAVING A TEMPERATURE

RATING OF AT LEAST 90°C.

THIS FURNACE MUST BE INSTALLED SO THERE ARE

PROVISIONS FOR VENTILATING AIR.

SHOULD OVERHEATING OCCUR, OR THE GAS SUPPLY

FAIL TO SHUT OFF, SHUT OFF THE MANUAL GAS

VALVE TO THE FURNACE BEFORE SHUTTING OFF THE

ELECTRICAL SUPPLY.

!

WARNING

THESE UNITS ARE NOT APPROVED FOR MOBILE

HOME APPLICATIONS. SUCH USE COULD RESULT IN

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

!

CAUTION

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR

PROPER INSTALLATION, ADJUSTMENT AND OPERATION

OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN IMPROPER INSTALLATION, ADJUSTMENT,

SERVICE OR MAINTENANCE POSSIBLY RESULTING

IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

!

WARNING

DO NOT USE OXYGEN TO PURGE LINES OR PRESSURIZE

SYSTEM FOR LEAK TEST. OXYGEN REACTS VIOLENTLY

WITH OIL, WHICH CAN CAUSE AN EXPLOSION

RESULTING IN SEVERE PERSONAL INJURY OR DEATH.

GAS-FIRED APPLIANCES ARE NOT DESIGNED FOR

USE IN HAZARDOUS ATMOSPHERES CONTAINING

FLAMMABLE VAPORS OR COMBUSTIBLE DUST,

IN ATMOSPHERES CONTAINING CHLORINATED

OR HALOGENATED HYDROCARBONS, OR IN

APPLICATIONS WITH AIRBORNE SILICONE

SUBSTANCES. SEE HAZARD LEVELS BELOW.

!

WARNING

!

WARNING

Before You Start

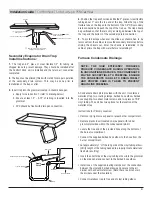

This unit is shipped with a cooling chassis installed in the cabinet.

Prior to installing the unit in the wall opening, the shipping bolts

located at the bottom on both sides of the cabinet must be

removed to allow for removal of the cooling chassis. 1/4" hole

plugs provided with the unit should be installed in the holes to

prevent air leakage. Shipping bolts are located on both sides below

this sticker:

THE SHIPPING BOLTS MUST BE REMOVED PRIOR

TO INSTALLATION OF THE CABINET TO PERMIT

REMOVAL OF THE CHASSIS. INSTALL THE HOLE

PLUGS PROVIDED.

14299588

This unit is designed and approved for through-the-wall

installation only. The unit must be installed a minimum of 8"

above finish floor. If this unit is installed in a residential garage,

it must be installed so that the ignition source and burners are

located not less than 18 inches (457 mm) above the floor, and

it must be located or protected to avoid physical damage by

vehicles. The entire unit must not be installed outside.

The grille

side of the unit should extend 3/4" beyond the exterior wall to allow

moisture that may enter the outdoor section to drain. The pitch

of the internal drain pans toward the outside will assure proper

drainage when the cabinet is installed level.

Masonry walls must

have a lintel to support the wall.

The interior of the unit may be installed with zero clearances to

adjacent combustible surfaces.

The unit shall not be installed

directly on carpeting, tile or other combustible material, except

wood flooring.

In order to be able to remove the chassis, 40" of

open area must be left unobstructed in front of the access panels.

The 3/4" O.D. drain pan connection should be connected to the

building drain using the flexible tubing included and a trap. The

Содержание Comfort Pack CP9 T Series

Страница 2: ...2...