Installation Guide

|

Comfort Pack T Series

with up to

95% Gas Heat

22

Ignition System

This heater is equipped with a direct spark integrated control

system. The system monitors the safety devices and controls

the operation of the blower and venter motors and the gas valve

between heat cycles. It also controls the blower for cooling.

Ignition System Operating Sequence

– On a call for heat from the thermostat, the system energizes

the venter motor and goes through a 30-second prepurge. The

system verifies that the pressure switch, the high limit and the

flame rollout switch are in the closed state. The gas valve is then

energized and the ignition system provides the high voltage spark

to the electrode to ignite the main burner gas. Burner flame is

electronically sensed by the control upon carry over of flame. (A

separate solid metal probe is used as the flame sensing function.

A low voltage electrical signal is imposed on the metal probe that

is electrically isolated from ground. When the flame impinges

on the flame sensing probe, the flame acts as a conduction path

to ground. The flame rectifies and completes the DC circuit and

the ignition system acknowledges the flame.) The fan motor is

energized by the system after 20 seconds of flame sensing.

After the thermostat has been satisfied, the system de-energizes

the gas valve, the venter motor goes through a 30-second post-

purge and the fan motor remains energized for an additional time.

Undesired Flame

– If flame is sensed while the gas valve is

de-energized, the control shall energize the venter motor and

blower motor on heat speed. When flame is no longer sensed, the

venter motor will run through post-purge, and the blower motor

will run through the selected heat blower off delay time. The control

will do a soft lockout, but will still respond to open limit and flame.

The FLAME (yellow) LED shall flash rapidly when lockout is due to

undesired flame.

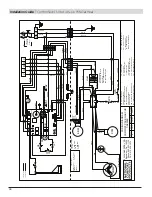

ROUTE THE WIRES SO THAT THEY DO NOT

CONTACT THE FLUE GAS COLLECTION BOX

OR VENTER HOUSING. CONSULT THE WIRING

DIAGRAM SUPPLIED WITH YOUR HEATER.

IF ANY OF THE ORIGINAL WIRES AS

SUPPLIED WITH THE APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH

WIRING MATERIAL HAVING A TEMPERATURE

RATING OF AT LEAST 105°C, EXCEPT FOR

LIMIT CONTROL, FLAME ROLLOUT SWITCH

AND SENSOR LEAD WIRES, WHICH MUST

BE 150°C. PLEASE SEE “HAZARD INTENSITY

LEVELS”.

!

CAUTION

NOTE:

This is a fire trial system. Should the unit

not sense burner flame, two additional tries will

be made. If the unit does not sense flame in three

tries, it will lockout for one hour before initiating

another 3-sequence trial for ignition. To initiate

another trial for ignition before the one hour

elapses requires that either the thermostat be

reset or the power to the unit be interrupted for

30 seconds. The user should not continue to try

resetting the system. Contact a qualified service

agency.

Combustion Air Proving Switches

The combustion air proving switches are pressure sensitive

switches that monitor air pressure to ensure that proper combustion

air flow is available. The switches are single pole/normally open

devices that close when a decreasing pressure is sensed in the

venter housing, or condensate collection box.

On start-up when the heater is cold, the sensing pressure is at

the most negative level, and as the heater warms up, the sensing

pressure becomes less negative. After the system has reached

equilibrium (about 10 minutes), the sensing pressure levels off.

If a restriction causes the sensing pressure to be outside the

switch setpoint, the pressure switch will function to shut off the

main burner. The main burner will remain off until the system has

cooled and/or the resistance is reduced. The Table below lists the

approximate water column negative pressure readings and switch

setpoints for sea level operating conditions.

Heat Module

CHS0043

CHS0050

Collector Box

Pressure Switch

OPENS

-0.3+/-0.05

-0.6+/-0.05

CLOSES

-0.45 Max

-0.75 Max

Inducer

Pressure Switch

OPENS

-0.9+/-0.05

-0.7+/-0.05

CLOSES

-1.05 Max

-0.85 Max

Limit Switches

All units are equipped with a temperature activated auto reset limit

control. The control is factory set and is non-adjustable. If the setpoint

is reached, the limit control acts to interrupt the electric supply to

the gas valve. These safety devices provide protection in the case of

motor failure or lack of airflow due to a restriction at the inlet or outlet.

Limit Switch Operation

– The limit switches are ignored unless a

call for heat is present (W energized). If the limit switch is open and

a call for heat is present, the control de-energizes the gas valve and

Содержание Comfort Pack CP9 T Series

Страница 2: ...2...