Chapter 5 Maintenance and Inspection

UD-series Screw Compressor

5.5 Reassembly

5-44

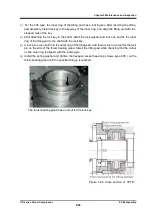

Cut-out part of the main bearing

b

)

Cut the bearing head gasket along the inner edge (important for thrust adjustment).

Bearing

head gaskets are asymmetrical, so check if they are in the correct position.

c

)

Insert the parallel pin through the flange before tightening the hexagon socket head cap

screw (part number 2).

5.5.3

Rotor

Mating Mark on the M Rotor

Mating Mark on the F Rotor

a

)

First, apply oil to the bearing head side shaft of the F rotor, and also apply oil to the inside of

the main bearing.

Install from F rotor to rotor casing.

Use a crane or chain block to hang the center of the rotor,

balance the front and back, and install half of the rotor in the rotor casing, then remove the

hanging belt and push the rotor in.

(

If the robe of both rotors can be correctly mesh as in steps

b) and c), the M rotor may be installed first. )

The rotor robes have robe mark (engraved) on both the discharge side and suction side.

In

that case, even if you install the M rotor first, you can check the combined engraving of the

robes.