ENGINE MAIN PARTS - INSPECTION AND CORRECTION

2 - 28

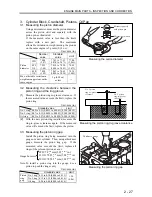

3.4 Measuring the clearance between the

piston pin and the pin boss

Measure the piston pin diameter. Measure the

bore size of the piston pin boss. If the difference

between them exceeds the limit, replace with

new parts.

Unit: mm (in.)

Nominal

value

Standard

value

Limit

Piston pin

diameter

φ

23

(0.9062)

22.944 to 23.000

(0.9039 to 0.9062)

―

Piston

pin-to-boss

clearance

―

0.006 to 0.018

(0.0002 to 0.0007)

0.050

(0.002)

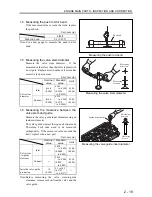

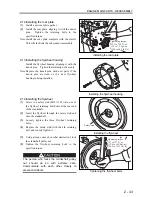

3.5 Measuring the connecting rod bend and

twist

(1)

Measure

C

and

l

as illustrated. If measured C is

more than 0.05 mm (0.0020 in.) per 100 mm

(3.937 in.) of measured

l

, correct the connecting

rod using a press.

Unit: mm (in.)

Standard value

Limit

Connecting rod

bend and twist

0.05/100

(0.002/3.940)

or less

0.15/100

(0.006/3.940)

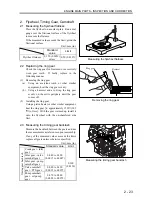

(2)

Normally, a connecting rod aligner is used to

measure the connecting rod for bend and twist.

Note: Before measuring the connecting rod for bend,

tighten the connecting rod cap nuts to the

specified torque.

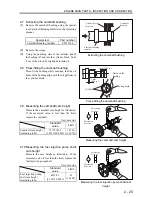

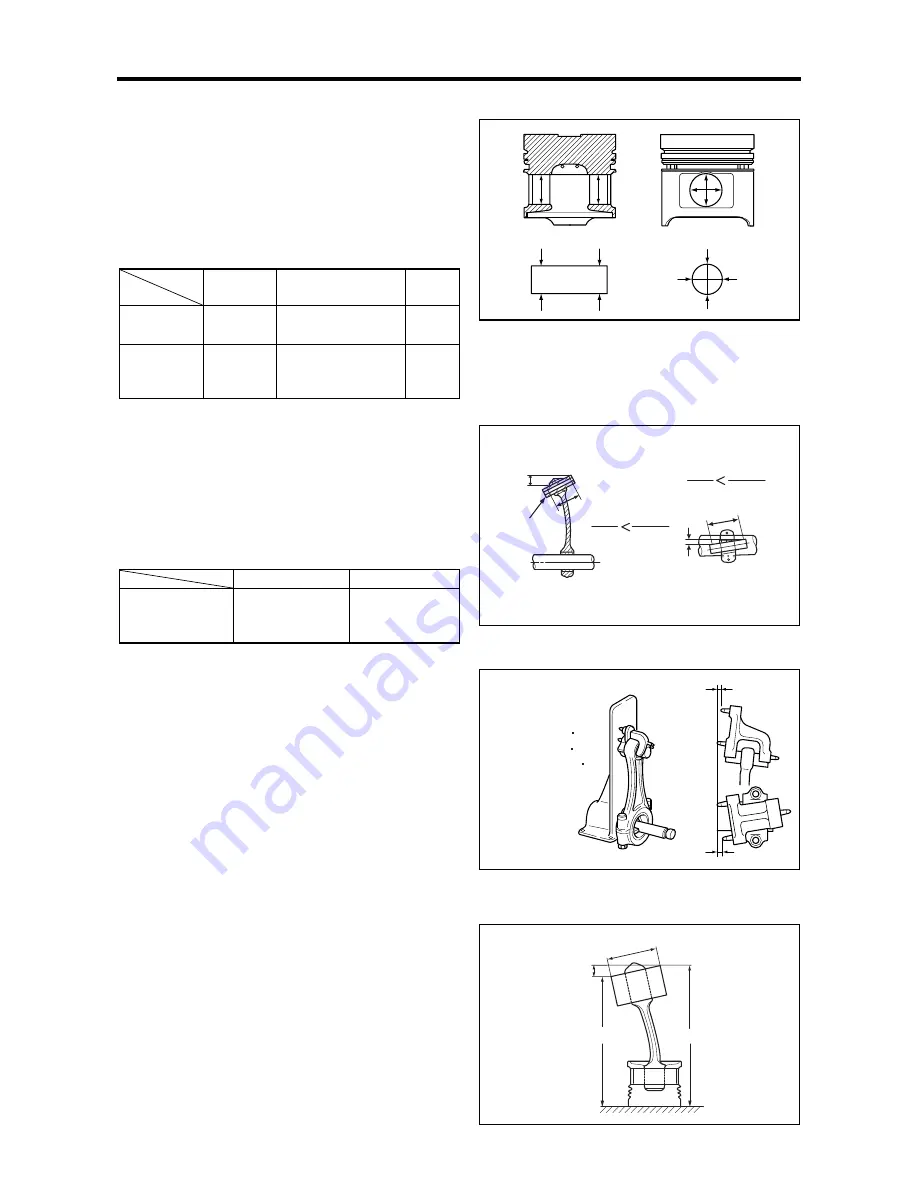

(3)

When measuring connecting rod bend with the

piston installed to the connecting rod, place the

piston/rod assembly on a surface plate such that

the top of piston lies on the plate. Then, insert a

round rod with the same diameter as the crank pin

into the connecting rod large end. Using a dial

gauge, measure the top of the round rod for any

variation in height.

Measuring the piston pin-to-boss clearance

Measuring the connecting rod bend and twist

Using a connecting rod aligner to measure

the rod bend and twist

Using a dial gauge to measure

the connecting rod for bend

Measuring

location

Measuring

direction

A

B

C

D

Piston pin

C

C

C

100

0.05

C

100

0.05

Connecting rod twist

Connecting rod bend

l

l

l

l

Tightening torque

for connecting

rod cap nut

32.4 to 37.3 N m

(3.3 to 3.8 kgf m)

[23.9 to 27.5 lbf ft]

Содержание diesel engines

Страница 5: ......

Страница 33: ...SERVICE STANDARDS 1 20 ...

Страница 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Страница 37: ...TOOLS LIST 1 24 ...

Страница 38: ...1 Identifying the Timing for Overhaul 1 26 2 Measuring the Compression Pressure 1 27 OVERHAUL TIMING ...

Страница 41: ...OVERHAUL TIMING 1 28 ...

Страница 46: ......

Страница 47: ......

Страница 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Страница 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Страница 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Страница 117: ...FUEL SYSTEM INSTALLATION 3 26 1 Fuel Injection Pumps Installing the fuel injection pumps Installation sequence ...

Страница 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Страница 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Страница 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Страница 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Страница 150: ......

Страница 151: ......

Страница 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Страница 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Страница 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Страница 161: ...ELECTRICAL SYSTEM REMOVAL 7 2 1 Starter Removal of the starter Removal sequence Harness Bolt Starter ...

Страница 164: ...ELECTRICAL SYSTEM REMOVAL 7 5 4 Glow Plug Removal of the glow plug Removal sequence Glow plug Connection plate ...

Страница 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Страница 184: ...1 Glow Plug 7 26 2 Stop Solenoid 7 27 3 Alternator 7 28 4 Starter 7 29 ELECTRICAL SYSTEM INSTALLATION ...

Страница 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Страница 207: ...MISCELLANEOUS 9 4 ...