ENGINE MAIN PARTS - INSPECTION AND CORRECTION

2 - 18

1. Cylinder Head, Valve Mechanism

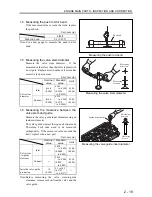

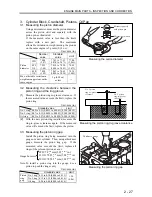

1.1 Measuring the cylinder head bottom face

distortion

Using a straight edge across the bottom face of

the cylinder head and a thickness gauge, measure

for any distortion. If the measured distortion

exceeds the limit, correct with a surface grinder.

Unit: mm (in.)

Standard

value

Limit

Cylinder head bottom

face distortion

0.05 less

(0.002 less)

0.10

(0.004)

1.2 Measuring the rocker arm bore and the

rocker shaft diameter

Measure the rocker arm bore and the rocker shaft

diameter to obtain the arm-to-shaft clearance. If

the clearance is between the standard value and

the limit, replace the rocker arm. If the clearance

is equal to or exceeds the limit, replace both the

rocker arm and shaft.

Unit: mm (in.)

Nominal

value

Standard value

Limit

Rocker arm

inner

diameter

φ

19

(0.749)

18.910 to 18.930

(0.7450 to 0.7458)

―

Rocker shaft

diameter

φ

19

(0.749)

18.880 to 18.898

(0.7438 to 0.7445)

―

Arm-to-shaft

clearance

―

0.012 to 0.050

(0.0005 to 0.002)

0.200

(0.0079)

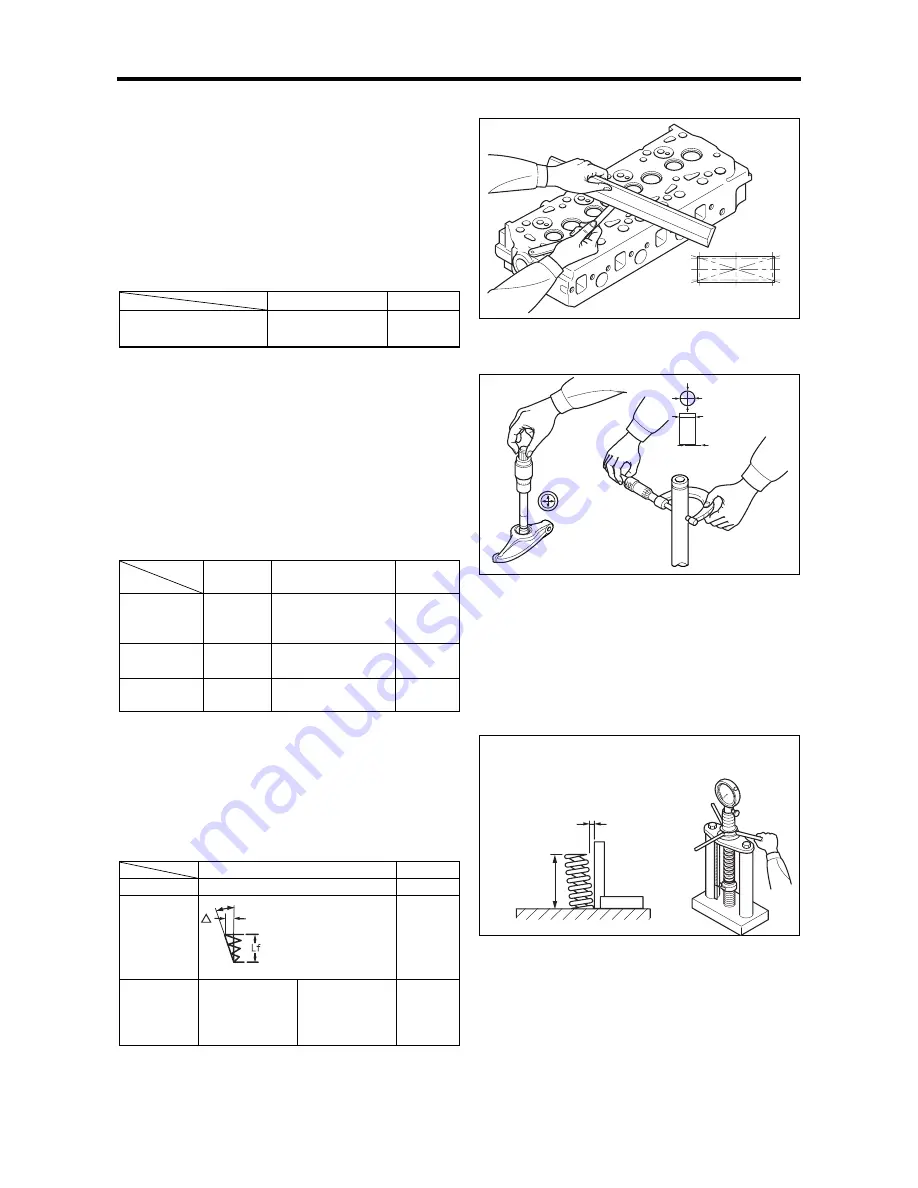

1.3

Measuring the valve spring for

squareness and free length

Measure the valve spring for squareness, free

length, etc. If any of the measured values

exceeds the limit, replace the spring.

Unit: mm (in.)

Standard value

Limit

Free length

47 (1.85)

46 (1.81)

Squareness

θ

=2.0º or less

△

(gap)=0.2 (0.0079)

or less

Lf=47 (1.8504)

△

=0.5

(0.0197)

across the

entire

length

Installed

length/load

mm (in.)/N

(kgf) [lbf]

39.0 (1.536)/

131 to 145

(13.3 to 14.7)

[29 to 33]

30.1 (1.185)/

279 to 309

(28.5 to 31.5)

[63 to 69]

-15%

Measuring the rocker arm inner diameter

and the rocker shaft diameter

Measuring the cylinder head bottom face

for distortion

θ

Measuring the spring for squareness

and free length

Measuring locations

and directions

Measuring

direction

Measuring

direction

Measuring

location

Free length

Spring squareness (gap)

Содержание diesel engines

Страница 5: ......

Страница 33: ...SERVICE STANDARDS 1 20 ...

Страница 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Страница 37: ...TOOLS LIST 1 24 ...

Страница 38: ...1 Identifying the Timing for Overhaul 1 26 2 Measuring the Compression Pressure 1 27 OVERHAUL TIMING ...

Страница 41: ...OVERHAUL TIMING 1 28 ...

Страница 46: ......

Страница 47: ......

Страница 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Страница 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Страница 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Страница 117: ...FUEL SYSTEM INSTALLATION 3 26 1 Fuel Injection Pumps Installing the fuel injection pumps Installation sequence ...

Страница 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Страница 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Страница 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Страница 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Страница 150: ......

Страница 151: ......

Страница 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Страница 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Страница 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Страница 161: ...ELECTRICAL SYSTEM REMOVAL 7 2 1 Starter Removal of the starter Removal sequence Harness Bolt Starter ...

Страница 164: ...ELECTRICAL SYSTEM REMOVAL 7 5 4 Glow Plug Removal of the glow plug Removal sequence Glow plug Connection plate ...

Страница 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Страница 184: ...1 Glow Plug 7 26 2 Stop Solenoid 7 27 3 Alternator 7 28 4 Starter 7 29 ELECTRICAL SYSTEM INSTALLATION ...

Страница 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Страница 207: ...MISCELLANEOUS 9 4 ...