ENGINE MAIN PARTS - INSPECTION AND CORRECTION

2 - 27

3. Cylinder

Block,

Crankshaft, Pistons, Oil Pan

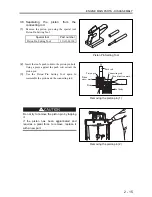

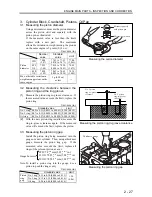

3.1 Measuring the piston diameter

Using a micrometer, measure the piston diameter

across the piston skirt and squarely with the

piston pin, as illustrated.

If the measured value is less than the limit,

replace with a new part. The maximum

allowable variation in weight among the pistons

on the same engine is 5 grams (0.18 oz).

Unit: mm (in.)

Nominal

value

Standard

value

Limit

STD

78.00

(3.07)

77.93 to 77.95

(3.070 to 3.071)

77.80

(3.065)

0.25

OS

78.25

(3.08)

78.18 to 78.20

(3.080 to 3.081)

78.05

(3.075)

Piston

diameter

0.50

OS

78.50

(3.09)

78.43 to 78.45

(3.090 to 3.090)

78.30

(3.085)

Max. allowable variation in

weight among pistons on the

same engine:

5 g (0.18 oz)

or less

―

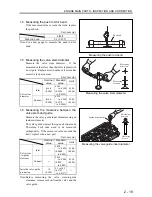

3.2 Measuring the clearance between the

piston ring and the ring groove

(1)

Measure the piston ring-to-groove clearance. If

the measured value exceeds the limit, replace the

piston ring.

Unit: mm (in.)

Standard

value Limit

No. 1 ring 0.09 to 0.11 (0.0035 to 0.0043) 0.300 (0.012)

No. 2 ring 0.07 to 0.11 (0.0028 to 0.0043) 0.200 (0.008)

Oil ring

0.03 to 0.07 (0.0012 to 0.0028) 0.200 (0.008)

(2)

With the new piston ring installed, measure the

ring-to-groove clearance again. If the measured

value still exceeds the limit, replace the piston.

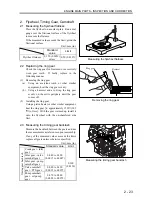

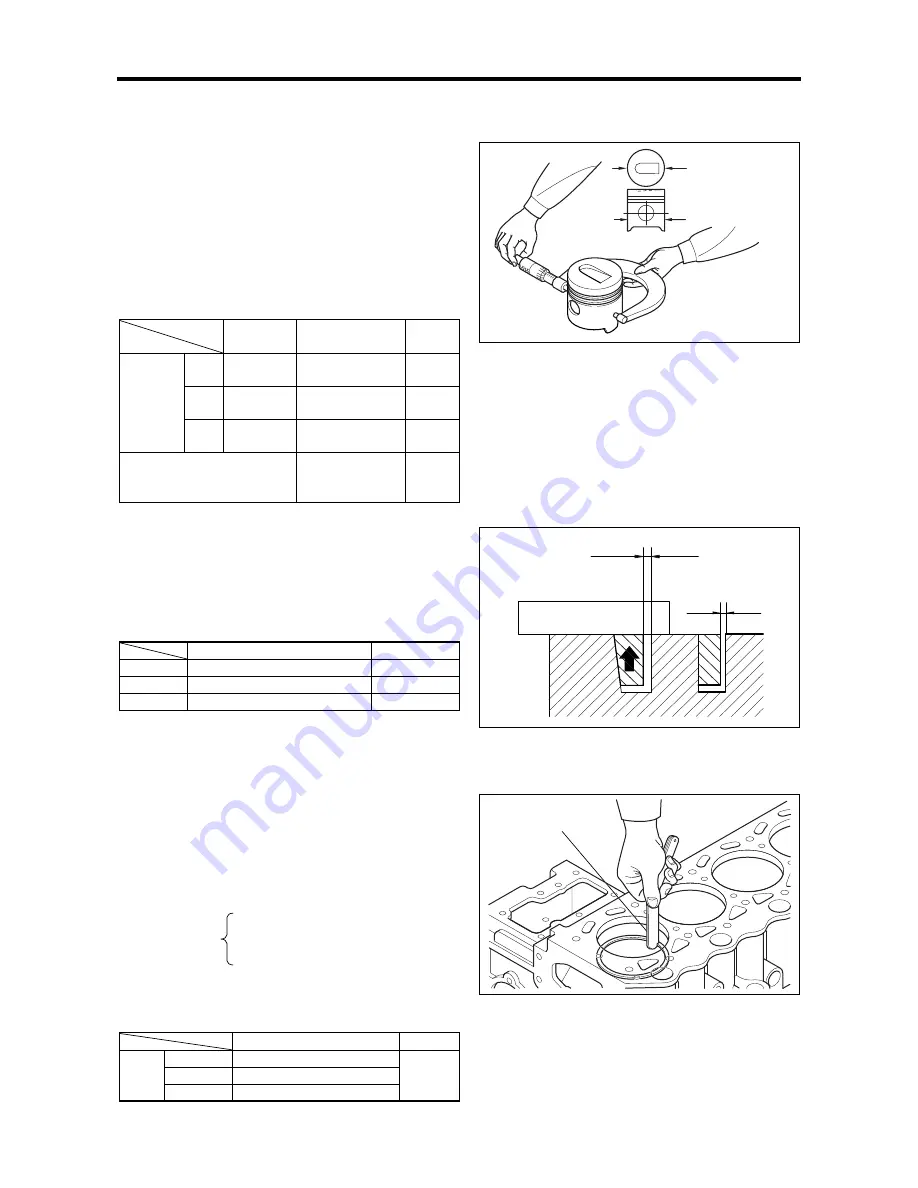

3.3 Measuring the piston ring gap

Install the piston ring being measured into the

gauge or a new cylinder. Then, using a thickness

gauge, measure the piston ring gap. If the

measured value exceeds the limit, replace all

rings of the relevant piston as a set.

STD=78

+0.03

0

mm (3.07

+0.0012

0

in.)

Gauge bore size 25 OS=78.25

+0.03

0

mm (3.08

+0.0012

0

in.)

50 OS=78.50

+0.03

0

mm (3.09

+0.0012

0

in.)

Note: To install a piston ring into the gauge, use a

piston to push the ring evenly.

Unit: mm (in.)

Standard

value

Limit

No. 1 ring 0.15 to 0.30 (0.006 to 0.012)

No. 2 ring 0.15 to 0.35 (0.006 to 0.014)

Piston

ring

gap

Oil ring

0.20 to 0.40 (0.008 to 0.016)

1.50

(0.06)

Measuring the piston diameter

Measuring the piston ring-to-groove clearance

Measuring the piston ring gap

Measuring location

Measure squarely

with piston pin

Thickness gauge

No. 1 piston

ring-to-groove

clearance

No. 2 piston

ring-to-groove

clearance

Содержание diesel engines

Страница 5: ......

Страница 33: ...SERVICE STANDARDS 1 20 ...

Страница 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Страница 37: ...TOOLS LIST 1 24 ...

Страница 38: ...1 Identifying the Timing for Overhaul 1 26 2 Measuring the Compression Pressure 1 27 OVERHAUL TIMING ...

Страница 41: ...OVERHAUL TIMING 1 28 ...

Страница 46: ......

Страница 47: ......

Страница 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Страница 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Страница 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Страница 117: ...FUEL SYSTEM INSTALLATION 3 26 1 Fuel Injection Pumps Installing the fuel injection pumps Installation sequence ...

Страница 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Страница 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Страница 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Страница 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Страница 150: ......

Страница 151: ......

Страница 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Страница 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Страница 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Страница 161: ...ELECTRICAL SYSTEM REMOVAL 7 2 1 Starter Removal of the starter Removal sequence Harness Bolt Starter ...

Страница 164: ...ELECTRICAL SYSTEM REMOVAL 7 5 4 Glow Plug Removal of the glow plug Removal sequence Glow plug Connection plate ...

Страница 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Страница 184: ...1 Glow Plug 7 26 2 Stop Solenoid 7 27 3 Alternator 7 28 4 Starter 7 29 ELECTRICAL SYSTEM INSTALLATION ...

Страница 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Страница 207: ...MISCELLANEOUS 9 4 ...