ENGINE - INSPECTION

/

ADJUSTMENT, RUNNING-IN TRIAL AND PERFORMANCE TEST

8 - 12

2. Running-in

Trial

Whenever the engine is reassembled after overhaul,

run in the engine on a dynamometer. While the

engine is being run-in, also perform the inspections

listed below.

2.1 Starting the engine

(1)

Before starting the engine, check the levels of

coolant, engine oil and fuel. Also, bleed the

fuel and cooling systems of air.

(2)

With fuel shut off, operate the starter for

approx. 10 seconds to crank the engine in order

to distribute oil throughout the engine.

(3)

Move the control lever slightly in the direction

of increased fuel delivery (moving the lever to

the full delivery position is not recommended).

Turn the starter key switch to the START

position to start the engine.

(4)

With the engine started, move the control lever

to the no-load, low idle position.

2.2 Inspecting the engine during running-in

While the engine is being run-in, check the

followings. If faulty, stop the engine. Locate

the cause and take appropriate actions to

eliminate it.

(1)

Oil pressure at the rated and low idle speeds

The oil pressure should be 0.29 to 0.39 MPa

(3.0 to 4.0 kgf/cm

2

) [42.07 to 56.57 psi] at the

rated speed, and 0.098 MPa (1.0 kgf/cm

2

)

[14.22 psi] or above at the low idle speed.

(2)

The coolant temperature, which should be 75

to 85

℃

(167 to 185

°

F

).

(3)

The temperature of engine oil in the oil pan,

which should be 60 to 95

℃

(140 to 194

°

F

).

(4)

There should be no leakages of oil, coolant or

fuel. Pay particular attention to the

turbocharger lubrication oil pipe connections.

(5)

Diesel knock should disappear as the coolant

temperature rises. Other than that, there

should be no noise.

(6)

The exhaust gas for any abnormal color or

smell.

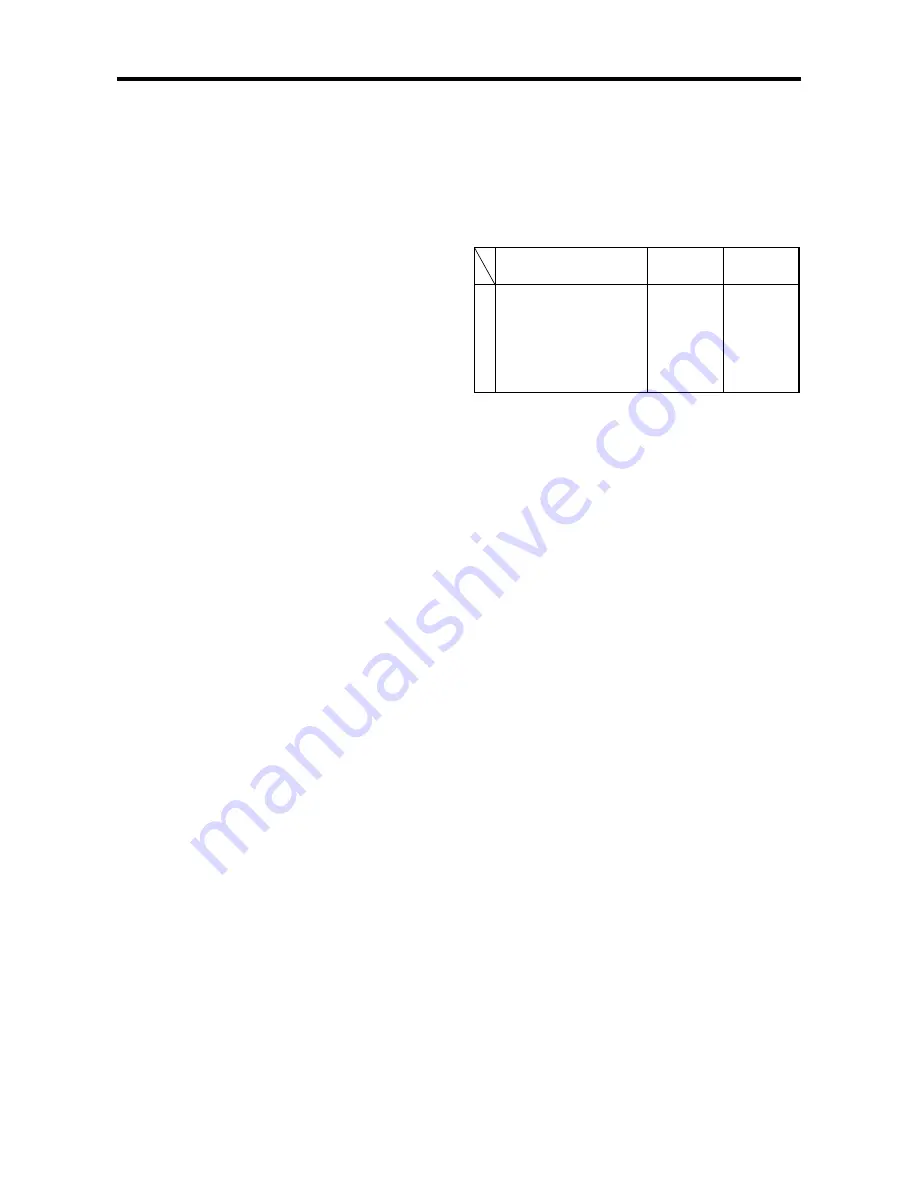

2.3 Running-in timetable

The following table shows the running-in

phases together with the relevant load and time

duration for each phase.

Running-in timetable

Engine speed

Load

(PS)

Time

(min)

1

2

3

4

5

6

Idle speed

1200

Rated speed

(varies depending on

engine specifications)

No load

No load

25 %

50 %

75 %

100 %

5

10

10

10

30

20

2.4

Inspection and adjustment after

running-in

(a)

Adjust the valve clearance

(b)

Inspect the fuel injection timing

(c)

Check the external bolts and nuts for

tightness

Содержание diesel engines

Страница 5: ......

Страница 33: ...SERVICE STANDARDS 1 20 ...

Страница 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Страница 37: ...TOOLS LIST 1 24 ...

Страница 38: ...1 Identifying the Timing for Overhaul 1 26 2 Measuring the Compression Pressure 1 27 OVERHAUL TIMING ...

Страница 41: ...OVERHAUL TIMING 1 28 ...

Страница 46: ......

Страница 47: ......

Страница 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Страница 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Страница 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Страница 117: ...FUEL SYSTEM INSTALLATION 3 26 1 Fuel Injection Pumps Installing the fuel injection pumps Installation sequence ...

Страница 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Страница 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Страница 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Страница 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Страница 150: ......

Страница 151: ......

Страница 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Страница 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Страница 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Страница 161: ...ELECTRICAL SYSTEM REMOVAL 7 2 1 Starter Removal of the starter Removal sequence Harness Bolt Starter ...

Страница 164: ...ELECTRICAL SYSTEM REMOVAL 7 5 4 Glow Plug Removal of the glow plug Removal sequence Glow plug Connection plate ...

Страница 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Страница 184: ...1 Glow Plug 7 26 2 Stop Solenoid 7 27 3 Alternator 7 28 4 Starter 7 29 ELECTRICAL SYSTEM INSTALLATION ...

Страница 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Страница 207: ...MISCELLANEOUS 9 4 ...