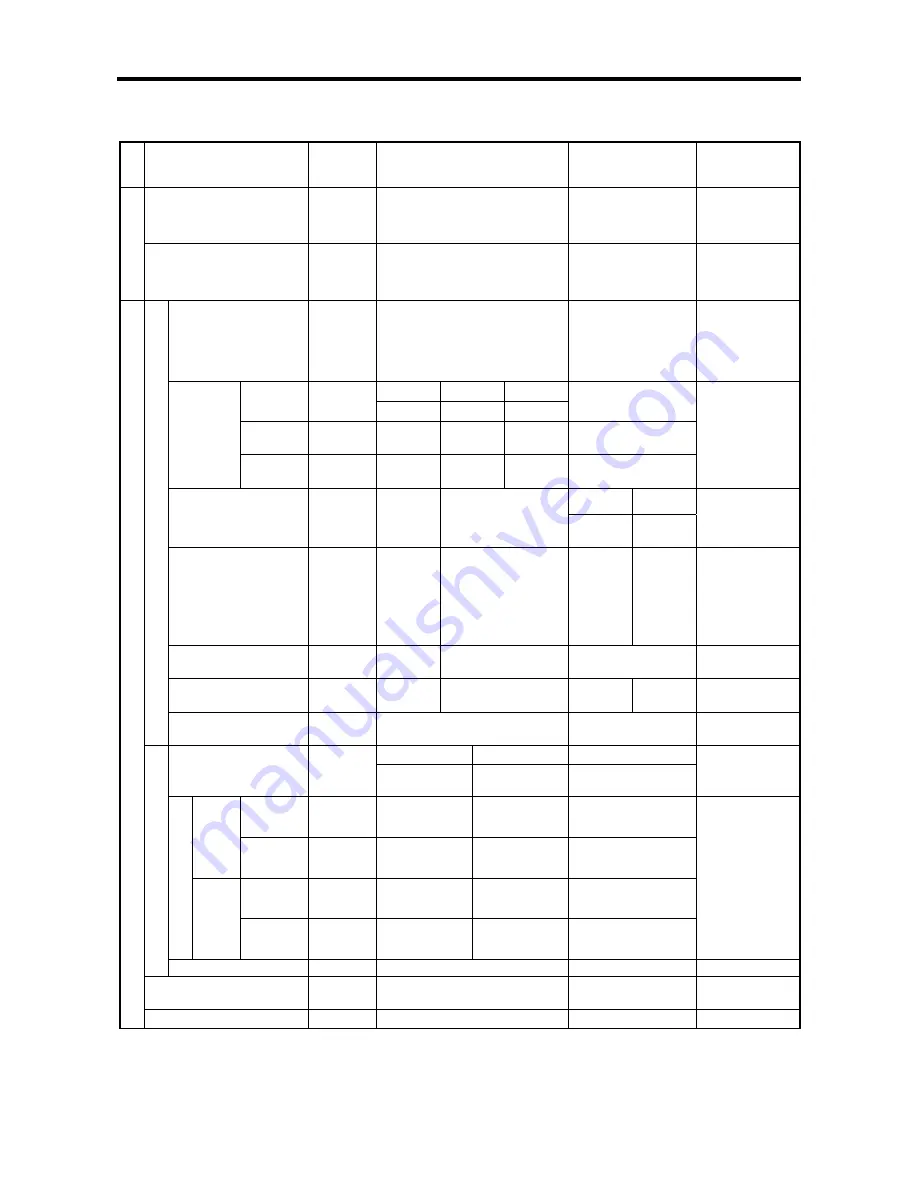

SERVICE STANDARDS

1 - 15

Unit: mm (in.)

Gro

up

Item

Nominal

value

Standard value

Limit

Remarks

Paper-element type air

cleaner

Clean every 100 hours

Replace every

500 hours

In

le

t an

d

ex

h

aus

t

s

y

st

em

s

Inlet

/

exhaust manifold

mounting face distortion

―

0.15 (0.006)

or less

Grind or

replace

Pinion gap

0.5 to 2.0

(0.02 to 0.08)

―

Adjust with

packing

M001T68281 M008T70471A M008T81071A

Terminal

voltage

11 V

11 V

23 V

―

Current

110 A

or less

130 A

or less

80 A

or less

―

No-load

character-

istics

Rotation

speed

2400

min

-1

3600

min

-1

3000

min

-1

―

Inspect

M001T68281

M008T70471A,

M008T81071A

Brush length

16.5

(0.65)

18.0

(0.71)

10.0

(0.39)

11.0

(0.43)

Replace

Brush spring load

17.5 to

23.7 N

(1.78 to

2.41 kgf)

[3.9 to 5.3

lbf]

29.4 to 39.2 N

(3.0 to 4.0 kgf)

[6.6 to 8.8 lbf]

6.90 N

(0.70 kgf)

[1.6 lbf]

13.7 N

(1.40 kgf)

[3.1 lbf]

Replace

Commutator radial

runout

0.05

(0.002)

0.03

(0.001)

0.10

(0.004)

Correct or

replace

Commutator diameter

29.4

(1.16)

32.0

(1.26)

28.8

(1.13)

31.4

(1.24)

Replace

St

ar

te

r

Mica undercutting

depth

0.5

(0.02)

0.2

(0.01)

Correct

A007T02071C A007TA8571

―

IC regulator

controlled voltage

[at 20

℃

(68

°

F

)]

14.7

±

0.3 V

28.5

±

0.5 V

Terminal

voltage

13.5 V

27.0 V

―

2500

min

-1

or

less

Current

32 A or above

18 A or above

―

Terminal

voltage

13.5 V

27.0 V

―

O

ut

put

c

ha

racter

ist

ics

(w

he

n hot

)

5000

min

-1

or

less

Current

47 A or above

22 A or above

―

Altern

at

or

Brush length

18.5 (0.73) 5.0

(0.20)

Replace

Clearance between stop

solenoid plunger and rack

0.15 to 0.20

(0.006 to 0.008)

Correct

Elec

tric

al sys

tem

Glow plug resistance

0.55

Ω

―

Replace

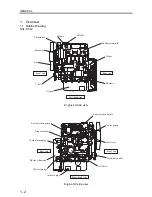

Содержание diesel engines

Страница 5: ......

Страница 33: ...SERVICE STANDARDS 1 20 ...

Страница 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Страница 37: ...TOOLS LIST 1 24 ...

Страница 38: ...1 Identifying the Timing for Overhaul 1 26 2 Measuring the Compression Pressure 1 27 OVERHAUL TIMING ...

Страница 41: ...OVERHAUL TIMING 1 28 ...

Страница 46: ......

Страница 47: ......

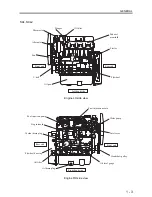

Страница 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Страница 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Страница 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

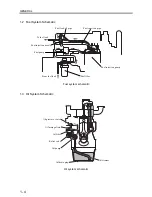

Страница 117: ...FUEL SYSTEM INSTALLATION 3 26 1 Fuel Injection Pumps Installing the fuel injection pumps Installation sequence ...

Страница 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Страница 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Страница 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Страница 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Страница 150: ......

Страница 151: ......

Страница 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Страница 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

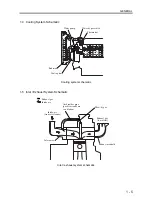

Страница 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Страница 161: ...ELECTRICAL SYSTEM REMOVAL 7 2 1 Starter Removal of the starter Removal sequence Harness Bolt Starter ...

Страница 164: ...ELECTRICAL SYSTEM REMOVAL 7 5 4 Glow Plug Removal of the glow plug Removal sequence Glow plug Connection plate ...

Страница 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Страница 184: ...1 Glow Plug 7 26 2 Stop Solenoid 7 27 3 Alternator 7 28 4 Starter 7 29 ELECTRICAL SYSTEM INSTALLATION ...

Страница 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Страница 207: ...MISCELLANEOUS 9 4 ...