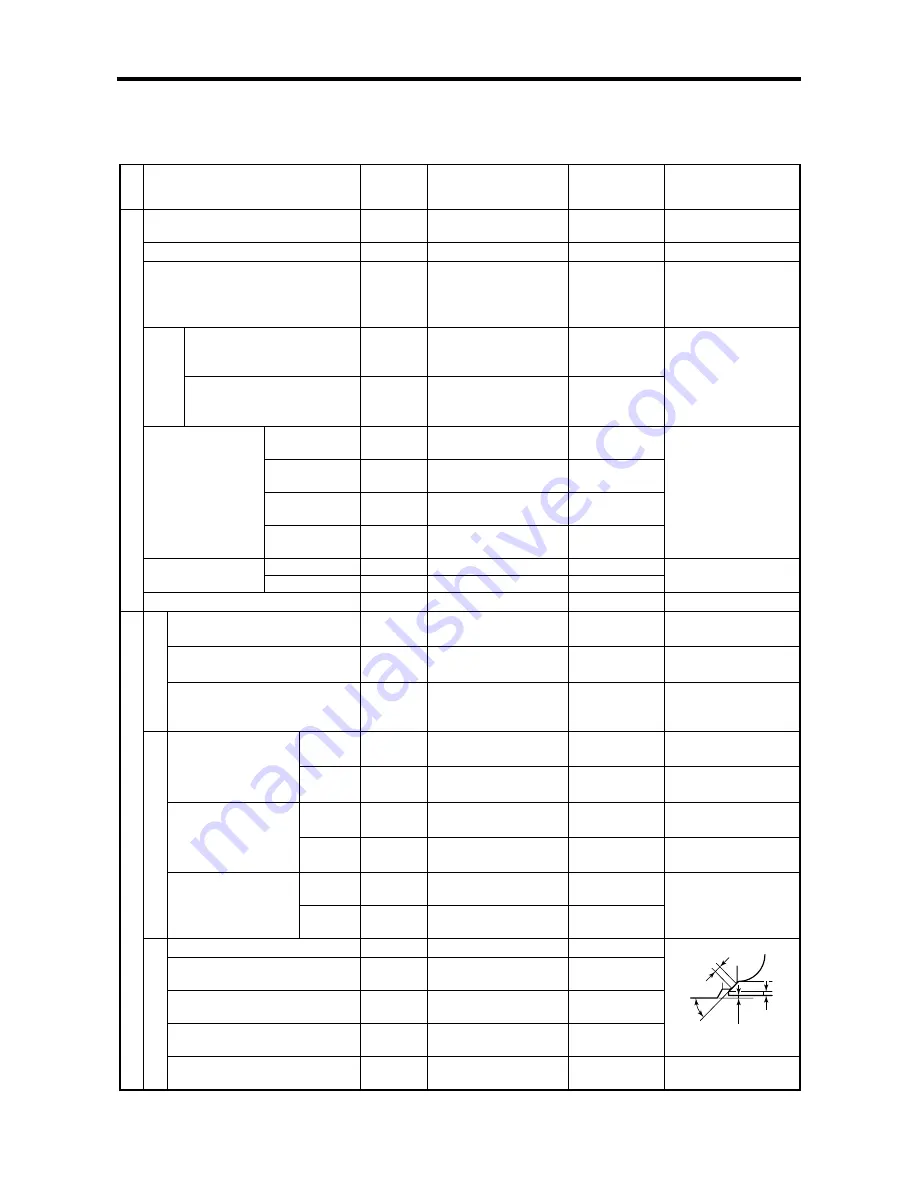

SERVICE STANDARDS

1 - 12

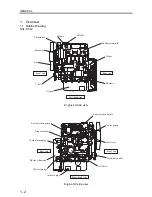

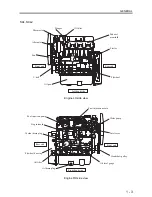

1. Service

Standards

Table

Unit: mm (in.)

Gro

up

Item

Nominal

value

Standard value

Limit

Remarks

Max. speed

(based on the rated speed)

2700

+30

-10

min

-1

Min. speed

1000

±

25 min

-1

Compression pressure

(at 290 min

-1

)

2.9 MPa (30 kgf/cm

2

)

[421 psi]

or above

2.6 MPa

(27 kgf/cm

2

)

[377 psi]

or less

Both oil and coolant

temperatures at 20 to

30

℃

(68 to 86

°

F

)

Rated speed

0.29 to 0.39 MPa

(3.0 to 4.0 kgf/cm

2

)

[42.07 to 56.57 psi]

En

gi

ne oi

l

pres

su

re

Low idle speed

0.098 MPa

(1.0 kgf/cm

2

)

[14.22 psi]

Oil temperature at

60 to 95

℃

(140 to

194

°

F

)

Inlet valve

open

BTDC 15

°

Inlet valve

closed

ABDC 41

°

Exhaust valve

open

BBDC 54

°

Valve timing [with

2 mm (0.079 in.)

clearance on the

valve side; cold

engine]

Exhaust valve

closed

ATDC 10

°

The theoretical valve

timing figures for

inspection vary from

the actual valve

timing.

Inlet valve

0.25 (0.01)

Valve clearance

Exhaust valve

0.25 (0.01)

Cold engine

Engine g

ene

ral

Fuel injection timing (BTDC)

17

°

Rocker arm inner diameter

φ

19

(0.749)

18.910 to 18.930

(0.7450 to 0.7458)

―

Rocker shaft diameter

φ

19

(0.749)

18.880 to 18.898

(0.7438 to 0.7445)

―

Ro

ck

er

Arm-to-shaft clearance

(oil clearance)

0.012 to 0.050

(0.0004

to 0.0019)

0.200

(0.0079)

Replace rocker arm.

Inlet

φ

6.6

(0.260)

6.565 to 6.580

(0.2586 to 0.2592)

6.500

(0.256)

Valve stem diameter

Exhaust

φ

6.6

(0.260)

6.530 to 6.550

(0.2572 to 0.2580)

6.500

(0.256)

Inlet

φ

6.6

(0.260)

6.600 to 6.615

(0.2600 to 0.2606)

Valve guide inner

diameter

Exhaust

φ

6.6

(0.260)

6.600 to 6.615

(0.2600 to 0.2606)

Inlet

0.020 to 0.050

(0.0008 to 0.0020)

0.100

(0.004)

Va

lv

e

Valve stem-to-guide

clearance

Exhaust

0.050 to 0.085

(0.0020 to 0.0033)

0.150

(0.006)

Replace valve and

valve guide.

Valve seat angle

45

°

Valve head sinkage

0

0.25 to 0.75

(0.0098 to 0.0295)

1.5

(0.0591)

Valve seat width

1.6

(0.063)

1.30 to 1.80

(0.0512 to 0.0709)

2.5

(0.0985)

Valve head margin

1.5

(0.0591)

1.35 to 1.65

(0.0531 to 0.0650)

0.5

(0.0197)

Engine mai

n

p

a

rt

s

V

alve seat a

nd

valve

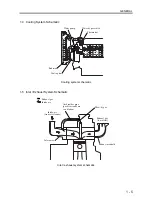

Installed valve guide protrusion

10

(0.394)

9.5 to 10.5

(0.3743 to 0.4137)

―

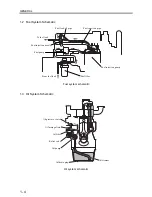

Valve seat width

Valve

seat

angle

Valve

head

margin

Valve head

sinkage

Содержание diesel engines

Страница 5: ......

Страница 33: ...SERVICE STANDARDS 1 20 ...

Страница 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Страница 37: ...TOOLS LIST 1 24 ...

Страница 38: ...1 Identifying the Timing for Overhaul 1 26 2 Measuring the Compression Pressure 1 27 OVERHAUL TIMING ...

Страница 41: ...OVERHAUL TIMING 1 28 ...

Страница 46: ......

Страница 47: ......

Страница 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Страница 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Страница 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Страница 117: ...FUEL SYSTEM INSTALLATION 3 26 1 Fuel Injection Pumps Installing the fuel injection pumps Installation sequence ...

Страница 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Страница 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Страница 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Страница 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Страница 150: ......

Страница 151: ......

Страница 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Страница 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Страница 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Страница 161: ...ELECTRICAL SYSTEM REMOVAL 7 2 1 Starter Removal of the starter Removal sequence Harness Bolt Starter ...

Страница 164: ...ELECTRICAL SYSTEM REMOVAL 7 5 4 Glow Plug Removal of the glow plug Removal sequence Glow plug Connection plate ...

Страница 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Страница 184: ...1 Glow Plug 7 26 2 Stop Solenoid 7 27 3 Alternator 7 28 4 Starter 7 29 ELECTRICAL SYSTEM INSTALLATION ...

Страница 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Страница 207: ...MISCELLANEOUS 9 4 ...