60

61

Maintenance

Inspection:

Before and after each use, spreader should be

inspected for loose, missing, or damaged mounting hardware,

parts, or safety guards. Spreader should also be inspected to

ensure it is securely attached to vehicle.

Cleaning:

Empty all material from spreader after each snow

or ice event. Wash entire spreader with soap and warm water

paying special attention to the conveyor drag chain. Do not

clean spreader with any corrosive chemicals or products that

contain chlorides or ammonium. Any commercially available

salt neutralizer may be applied.

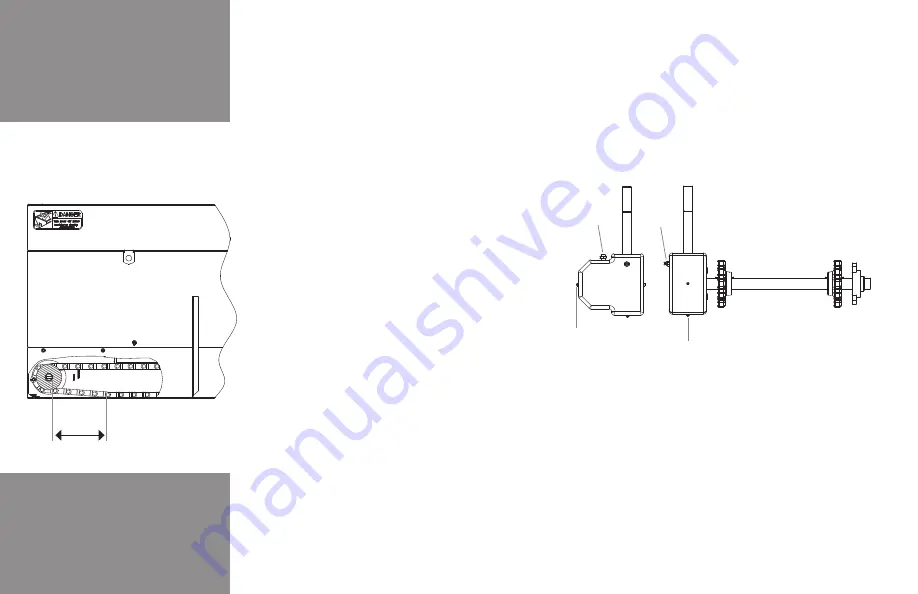

Adjusting Drag Chain Tension:

Loosen rear jam nut on

take-up bolt and tighten take-up bolt until drag chain is

properly tensioned. Drag chain is properly tensioned when

the distance between the centerline of the front idler and

point where chain contacts flange of longitudinal is between

( . . cm). oth sides of drag chain must be

adjusted evenly.

Adjusting V-belt/ Roller Chain Tension:

Loosen the gasoline

engine or electric motor mounting bolts and slide motor away

from gearbo (towards passenger side of vehicle) until proper

tension is achieved. Tighten motor mounting bolts to hold motor

in position. V-belt or roller chain should have between 1/4"– 5/16"

(. cm . cm) de ection midway between the sprockets.

Adjusting Spinner Roller Chain:

Loosen four spinner shaft

or spinner drive shaft ( olyhawk models only) mounting bolts

and slide shaft away from gearbo (towards passenger side

of

vehicle) until proper tension is achieved and shaft is straight

up and down, then tighten shaft mounting bolts to hold shaft

in position. Roller chain should have between 1/4" – 5/16"

deflection midway between sprockets. To prevent roller chain

failure, both sprockets must be realigned. For olyhawk

models spinner shaft may need to be aligned with the spinner

drive shaft after adjusting roller chain tension.

Gearbox Oil Level:

Check the gearbo oil level every

hours of operation or monthly. Gearbox should be filled until

oil reaches oil level plug. Oil should be flushed prior to start of

season and replaced with an W

gear type lubricant.

Electrical System:

Electrical system should be inspected for

loose connections and corrosion every hours of operation

or weekly. Dielectric grease should be applied to all electrical

connections.

General Maintenance

Gearbox Maintenance

Breather

Grease

Zerk

Drain Plug

Oil Level Plug

Drag Chain Tension

Adjustment

8.0"– 20.0"

(20.3cm – 50.8cm)

Maintenance

Gearbox

Input Shaft

Bearing

Bearings

Bearings

Lubrication

Transmitter Battery

Replacement

Lubrication:

After every hours of operation or weekly,

lubricate drag chain and roller chains with any commercial chain

lubricant or a mi ture of

motor oil

diesel fuel. After

every hours of operation or weekly, lubricate drive shaft,

spinner drive shaft and spinner shaft bearings with high quality

chassis grease. After every hours of operation or monthly,

lubricate gearbox input shaft bearing with high quality chassis

grease.

CAUTION:

over greasing gearbox input shaft bearing

will result in damage to the gearbox input shaft seal.

Wireless Remote Transmitter Battery Replacement:

Wireless controller transmitter battery should be replaced before

the start of each season. It is also recommended to keep a spare

battery with the vehicle. Wireless transmitter requires a standard

CR

lithium button cell battery.

1.

Gently press and slide off the battery cover from the

wireless transmitter.

2.

Remove the battery by sliding it out from underneath the

retainer. Do not attempt to remove the battery by lifting it

up from the retainer.

3.

Install new battery by sliding it under the retainer. Battery

must be installed with the positive ( ) symbol visible.

Electric Clutch:

The electric clutch on new spreaders and re-

placement clutches should be burnished before use to achieve

maximum torque. The clutch burnishing procedure is as follows:

1.

Idle Engine

2.

ngage clutch for seconds

3.

Disengage clutch for seconds

4.

Repeat steps ,

times to achieve ma imum

clutch torque.

At the end of the winter season remove the electric clutch, add a

coat of light oil to each mating half and store indoors to prevent

corrosion. Prior to start of next season, oil should be removed

and clutch should be reassembled onto spreader.

Gasoline Engine:

Follow engine manufacturer s maintenance

recommendations.

Содержание LPV 3

Страница 14: ...14 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 LPV Component Identification GASOLINE ENGINE...

Страница 16: ...16 ELECTRIC LPV Component Identification 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15...

Страница 18: ...18 PV Spreader Component Identification 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 GASOLINE ENGINE...

Страница 20: ...20 PV Spreader Component Identification ELECTRIC 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18...

Страница 22: ...22 PV Spreader Component Identification HYDRAULIC 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19...

Страница 24: ...24 GAS ENGINE Polyhawk Component Identification 1 2 3 4 5 6 8 9 10 11 12 13 14 15 16 17 18 19 7...

Страница 26: ...26 ELECTRIC Polyhawk Component Identification 1 2 3 4 5 6 8 9 10 11 12 7 13 14 15 16 17 18 19...

Страница 28: ...28 1 2 3 4 5 6 8 9 10 11 12 HYDRAULIC Polyhawk Component Identification 7 13 14 15 16 17 18 19 20...

Страница 53: ...53 Operating Instructions Left Right Pattern Left Spread Pattern Right Spread Pattern WindRow Spread Pattern...

Страница 71: ...71 Notes...

Страница 72: ...72...