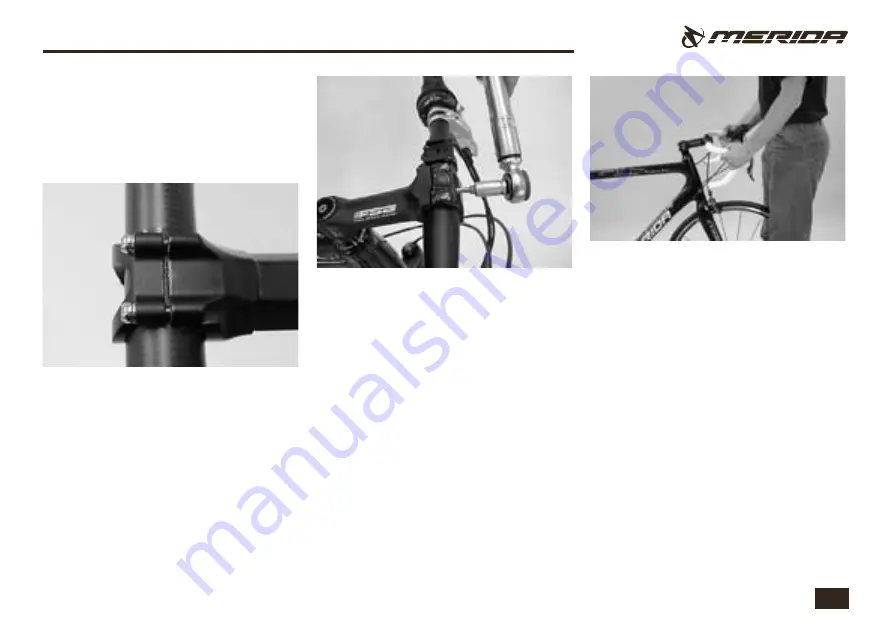

5. Screw in the bolts which have a greased

thread and head by a few turns with your

fingers. Screw in all bolts by hand until

they are snug. The clamping slot between

stem cap and stem body must be even with

the same gap at either end.

Check whether the handlebar is firmly seated

in the stem by trying to turn the handlebar

downwards. Furthermore, check whether you

can twist the handlebar/stem unit against

the fork. Take the front wheel between your

knees and try to turn the handlebar against

the wheel.

If the clamping of the handlebar or stem is still

not tight, increase the torque until you reach

the upper limit of the torque setting given by

the stem manufacturer.

With regard to the necessary torques, see

chapter 29.

“Recommended torques for

bolted connections”

. If the torques for two

components to be combined differ, make it a

rule to tighten them to the lower torque.

Check the firm seat once again, as described

above. If the clamping of the handlebar into

the stem or the stem onto the fork stem is not

properly tight, there is a dimensional compat-

ibility problem. In this case the stem should be

replaced by a compatible one.

8. Carbon handlebars and stems

6. Tighten the bolts of both clamping areas

alternately and gradually with a torque

wrench until you reach the lower limit of

the recommended torque. In the case of

stems with a 4-bolt front clamp, tighten the

bolts diagonally.