Reference Sheets for GRAFIK Eye Dimming Panel

36

Neon Tube Application

Information

Reference Sheet

Notes on Neon/Cold-Cathode Dimming

Overview

Successful dimming of neon and cold-cathode sources can be

achieved through proper equipment selection and installation. The

following installation suggestions and Luminous Tube Length Chart

for Dimming Applications must be used for optimum performance.

1. If equipment is selected and installed as specified here, a

dimming range of 95%-10% light should be possible.

2. The electrical properties of argon fill gas make it easier to dim

than red neon fill gas; therefore, installations using argon fill gas

will see a greater degree of success compared to neon

installations.

3. In addition to the following guidelines, all installations must

meet the NEC and local codes.

Lamps

1. Neon/cold-cathode lamps must be manufactured to proper lamp

pressurization (standard lamp pressure) without impurities. If

pressurization is not standard or impurities are present, poor

performance will result.

2. Neon/cold-cathode tubing should be well supported to avoid

rattling when dimmed.

3. Lutron recommends using only the transformer/tube

combinations spelled out in the Luminous Tube Length Chart for

Dimming Applications. Other combinations will result in poor

performance and flicker. Note that there are few successful

combinations for red neon tubes smaller than 11 mm.

4. Ends of tubes must be insulated to avoid arcing and subsequent

lamp instability.

Transformers

1. Normal power factor transformers must be used; electronic

transformers are not dimmable.

2. When choosing transformer secondary currents, it is important

to note that the higher the transformer current rating, the brighter

the light from the tube.

3. Transformers must be sized according to the chart. These

modified charts must be used by neon/cold-cathode transformer

suppliers to size the transformer for dimming applications. Stan-

dard luminous tube length charts must not be used to size

transformers in dimming applications as poor performance will

result.

4. Transformers must be thermally-protected or fused.

5. Power factor correction capacitors, if present must be

disconnected. If power correction is required, contact the toll-

free

Lutron Hotline

for details on power factor correction at the

lighting controller.

6. Transformers should be sized to run as close as possible to full

load footage as shown in the chart.

Wiring

1. Optimal dimming performance is achieved when the high voltage

(GTO-15) cable connecting a transformer output terminal to a

cold-cathode tube is enclosed in plastic conduit or run without

conduit. If code requires metal conduit, aluminum is preferred.

2. The total length of all GTO-15 cable connecting a transformer to

the cold-cathode tubes must be:

Twenty feet or Less if enclosed in plastic or no conduit; 6 ft. or

Less if enclosed in Metal Conduit

3. Braided or shielded GTO-15 cable must not be used for dimming

applications.

4. Lutron recommends that only one GTO-15 cable be run per

conduit.

5. All GTO-15 cables should be spaced a minimum of 4” from any

other GTO-15 cable.

6. Make sure spacing from tube ends to ground (earth) and other

tube ends is adequate to prevent arcing and subsequent lamp

instability.

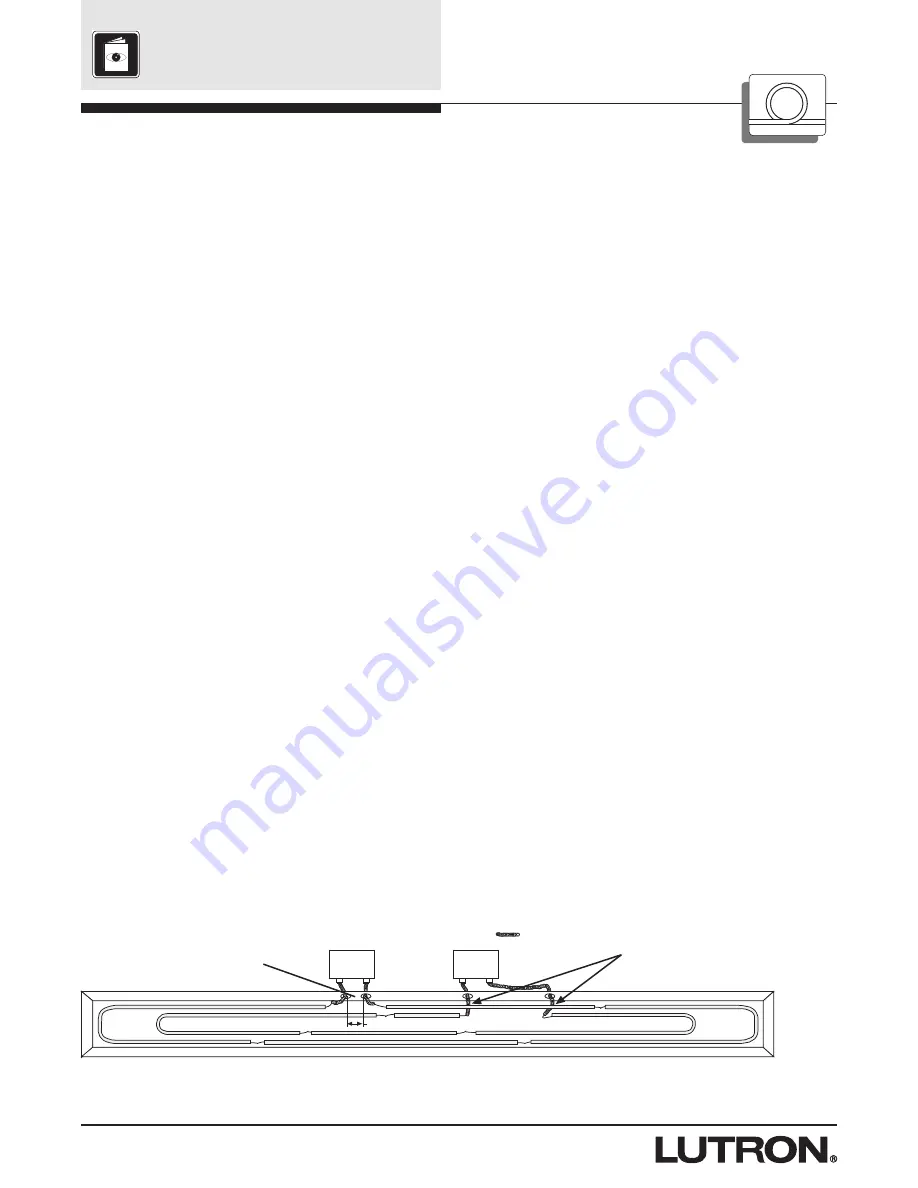

Note:

Make sure spacing between any tubing, tubing ends, high voltage secondary cable, or conduit to any grounded (earthed) surface is

adequate to prevent arcing and subsequent lamp instability.

1

2

> 4 in. (10 cm)

Any GTO-15 cable or conduit must be at least

4 in. (10 cm) from other GTO-15 cable or

conduit.

Total GTO-15 length per transformer must be < 20

ft. (9m) if in plastic or no conduit, or < 6 ft. (2m) if

in metal conduit.

GTO-15 Cable