Maintenance

60

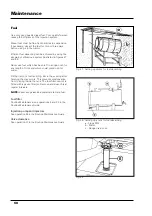

Fuel

Use only good quality diesel fuel. Poor quality fuel can

reduce the efficiency of the injection system.

Diesel fuel must be free from particles in suspension.

If necessary, decant the fuel for two or three days

before using it in the tractor.

Efficient fuel decanting can be achieved by using the

simple but efficacious system illustrated in figures 47

and 48.

Never use fuel which has been left in an open can for

any length of time and which could contain dirt or

water.

Fill the tractors fuel tank (Fig. 49) in the evening after

finishing the days work. This prevents condensation

from forming inside the tank. The fuel filter cap (d) is

fitted with a gauze filter (e). Remove and clean this at

regular intervals.

NOTE:

never use galvanized containers to store fuel.

Fig. 47 - Setting up drums for fuel decanting.

Fig. 48 - Setting up a tank for fuel decanting.

a - Slope 25%.

b - Water.

c - Sludge drain cock.

Fig. 49

Fuel filter

Routine Maintenance: see operations 5 and 33 in the

Routine Maintenance Guide.

Injection pump and injectors

See operation 44 in the Routine Maintenance Guide.

Valve clearance

See operation 31 in the Routine Maintenance Guide

.

Содержание 5860

Страница 28: ...Safety notes 24e Page left intentionally blank...

Страница 80: ...Maintenance 76 Page left intentionally blank...

Страница 88: ...Electrical system 84 Page left intentionally blank...

Страница 111: ...107 Table of contents Page N Technical specifications 108 Routine maintenance 109 Ground speed table 109 7860HC 8860 HC...

Страница 126: ...122 To ensure long and efficient service from your tractor use only spare parts and lubricants recommended by...

Страница 132: ...123 To ensure long and efficient service from your tractor use only spare parts and lubricants recommended by...