MAINTENANCE

7-41

1

D. Hydraulic System

Inspection and Maintenance of Hydraulic Equipment

CAUTION: During operation, the parts of the

hydraulic system become very hot.

Allow the machine to cool down before beginning

inspection or maintenance.

1. Park the machine following the same procedures as

described on page 7-7 for preparation of inspection/

maintenance work.

2. Begin servicing hydraulic components only after

components, hydraulic oil and lubricants are completely

cooled, and after releasing residual circuit pressures.

2.1 Release internal pressure.

2.2 Be sure to relieve the air pressure from the hydraulic oil

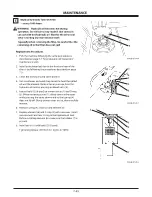

tank by pressing air bleed valve (1).

2.3 Allow the machine to cool down.

Note that servicing heated and pressurized hydraulic

components may cause hot parts and/or oil to fly off or

escape suddenly, possibly resulting in personal injury.

Keep body parts and face away from plugs or screws

when removing them.

Hydraulic components may be pressurized even when

cooled.

Service only on a flat, solid and level surface.

M4GB-07-044

Содержание 70Z7

Страница 2: ...93108 00691 April 2015...

Страница 5: ......

Страница 11: ...MACHINE NUMBERS 2 MEMO...

Страница 51: ...SAFETY LABELS S 40 6 10 4 1 3 9 6 5 SS 3461...

Страница 171: ...OPERATOR S STATION 1 110 MEMO...

Страница 173: ...BREAK IN 2 2 MEMO...

Страница 187: ...OPERATING THE ENGINE 3 14 MEMO...

Страница 231: ...OPERATING THE MACHINE 5 24 MEMO...

Страница 359: ...MAINTENANCE 7 118 MEMO...

Страница 363: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO...

Страница 367: ...STORAGE 10 4 MEMO...