J3020A Kit Installation Instructions

Page 14

1998-2006 Edition

This kit contains the following parts:

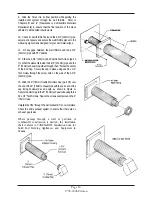

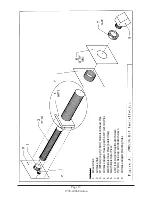

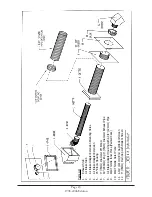

One Air intake adapter housing w/ 4-3/4” (121mm) air Intake pipe

One 4-3/4” (121mm) End Cap/ Rodent Screen

One 19” (483mm) length of 3” (76mm) exhaust pipe w/belled end

One Wall Thimble (2 pieces)

One 3” (76mm) Double Wall Rain Cap w/ Rodent Screen

Sixteen 1/2” #8 Hex Head self drilling & tapping Screws (Teck Screw)

Tools and other materials required:

Hand Drill with 1/4” Hex Driver

Appropriate Saw(s) to Cut 9” (229mm) Diameter Hole in Wall

Phillips Head Screw Driver

Power Drill, Phillips bit

Caulking gun with a tube of High Temperature RTV silicone

Wall Material

Wood

Sheet Metal

Masonry

Dry Wall

Recommended Screw Type

3/4” #6 Wood Screw

1/2” #6 Sheet Metal Screw

1-1/2” Molly Bolts

1” #6 sheet metal screws with plastic anchors

This kit contains all the materials, except 8 screws, that are needed to secure the wall thimble to the wall.

The type of screws needed depends on the type of wall material. The recommended type of screw for each

type of wall material is listed below:

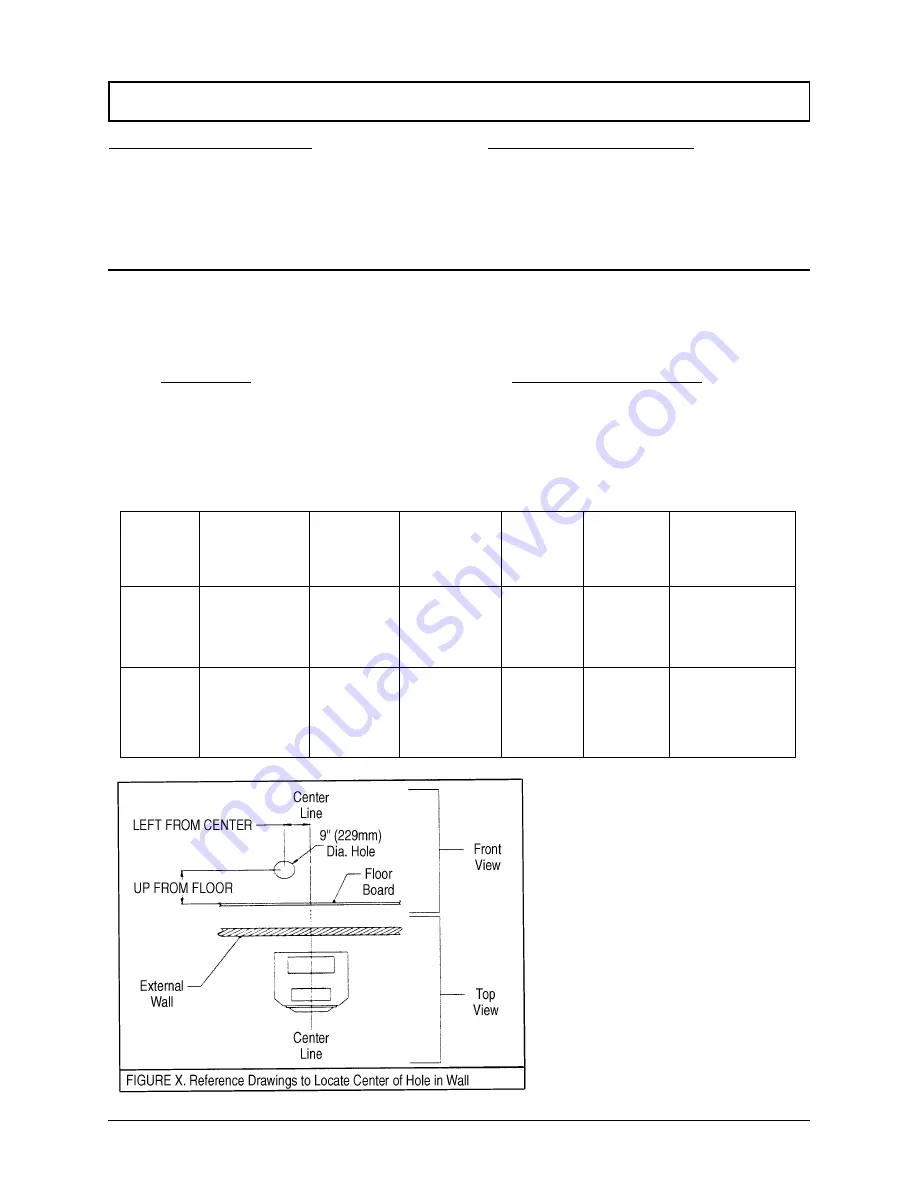

TABLE 1: Location Of Center Of 9" Hole In The

Wall

MODEL

J1000B w/

J1000B w/

J1000B

J2000T

J2000T

J2001T

Sheet Metal

Legs

Cast Legs

w/ Pedestal

W/ Pedestal w/ Cast Legs

LEFT

From

Center

Line

1/8"

(3mm)

1/8"

(3mm)

1/8"

(3mm)

1-5/8"

(41mm)

1-5/8"

(41mm)

1-5/8"

(41mm)

UP From

Floor Board

8-3/4" (222mm)

[add 1-3/4"

(45mm) if leg

balls are used]

10-1/2"

(267mm)

8-7/8"

(225mm)

13-1/2"

(343mm)

11-7/8"

(302mm)

4-1/2" (114mm)

[if using a riser add

riser height]

LEFT: Left of the center line as shown in Figure X.

UP: Up from the top of the floor board as shown in

Figure X.

1. Determine the final position for the stove and

refer to Chapters III and IV (Clearances to

Combustible Materials Requirements) to ensure

that the final position of the stove adheres to all

the listed requirements.

2. Determine the center of the 9" (229mm) hole

that needs to be cut in the wall by using Figures

X and the table above. Example: J1000 w/ Legs.

find the center line as in Figure 2. Move 1/8"

(3mm) to the left of the center line and up 8-3/4"

(222mm) from the floor. This point is the center of

the 9" (229mm) diameter hole.

Содержание J1000B

Страница 2: ......

Страница 8: ...Page vi 1998 2006 Edition ...

Страница 16: ...Page 8 1998 2006 Edition ...

Страница 20: ...Page 12 1998 2006 Edition ...

Страница 36: ...Page 28 1998 2006 Edition ...

Страница 38: ...Inside the Room and Recessed in an Interior Chase Page 30 1998 2006 Edition Recessed in an Exterior Chase ...

Страница 39: ...Corner Installation Page 31 1998 2006 Edition Installation requires standoffs to maintain clearances ...

Страница 44: ...Page 36 1998 2006 Edition ...

Страница 45: ...Page 37 1998 2006 Edition ...

Страница 46: ...VIII 5 Jamestown Control Panel Page 38 1998 2006 Edition ...

Страница 61: ...Page 53 1998 2006 Edition ...

Страница 62: ...Page 54 1998 2006 Edition ...

Страница 63: ...Page 55 1998 2006 Edition ...

Страница 64: ...Page 56 1998 2006 Edition ...

Страница 69: ...Page 61 1998 2006 Edition ...

Страница 70: ...Page 62 1998 2006 Edition ...

Страница 79: ...Appendix A 3 1998 2006 Edition ...

Страница 80: ...Appendix A 4 1998 2006 Edition ...

Страница 81: ...Appendix A 5 1998 2006 Edition ...

Страница 82: ...Appendix A 6 1998 2006 Edition ...

Страница 84: ...Appendix B 2 1998 2006 Edition ...

Страница 86: ...APPENDIX D EXHAUST BLOWER ASSEMBLY MODEL J1000 Appendix D 1 1998 2006 Edition Complete Assembly is Part 07DAA ...

Страница 87: ...APPENDIX E AUGER MOTOR BRACKET INSTALLATION Appendix E 1 1998 2006 Edition ...

Страница 90: ...Appendix F 3 1998 2006 Edition ...

Страница 93: ...APPENDIX H J1000 CROSSFLOW FAN Part 07EEG Appendix H 1 1998 2006 Edition ...

Страница 94: ...APPENDIX I 1 EXHAUST BLOWER ASSEMBLY MODEL J1000 Appendix I 1 1998 2006 Edition ...

Страница 96: ...SERVICE RECORD DATE SERVICED BY DESCRIPTION ...