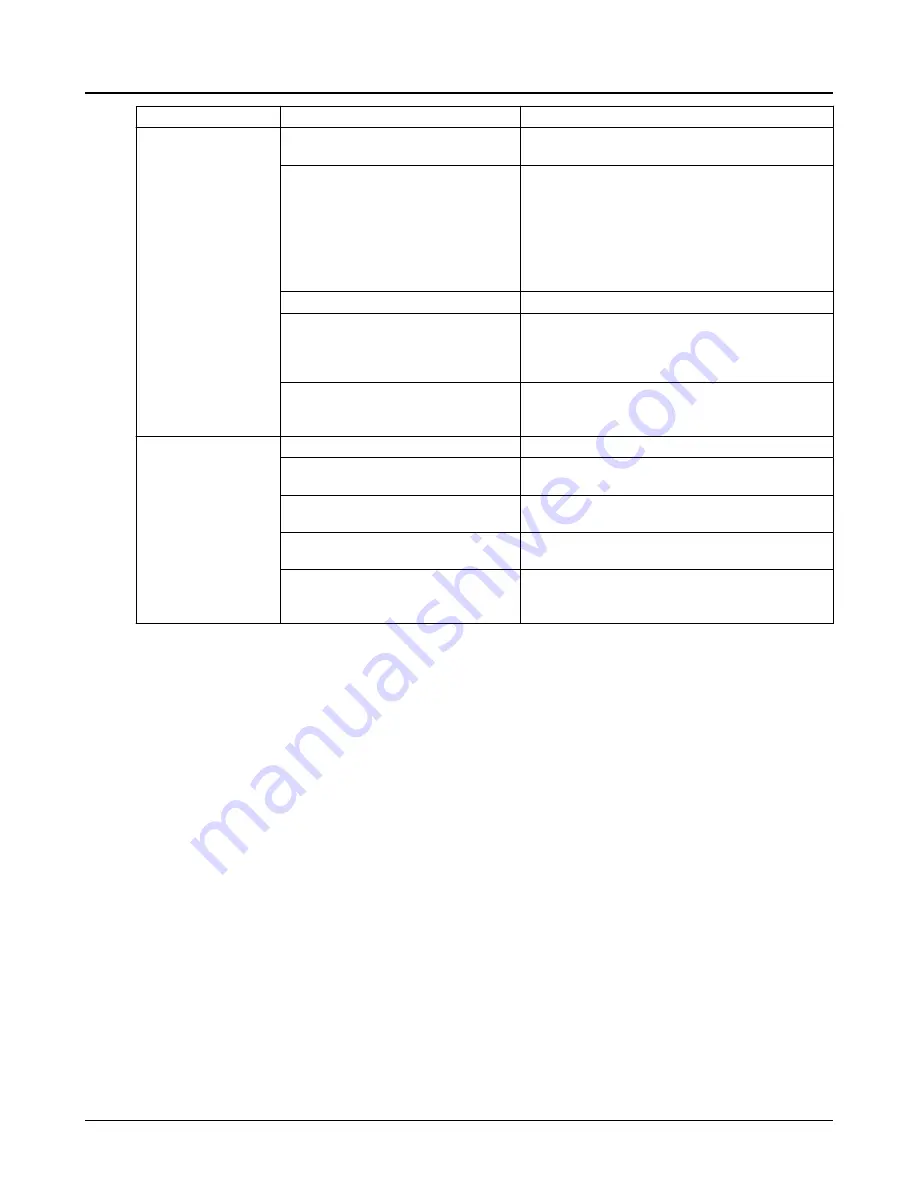

Symptom

Cause

Remedy

There is excessive pipe strain on the

pump casing.

Relieve the strain and check the alignment. Con-

sult ITT if necessary.

The amount of available NPSH is not

sufficient.

1.

Increase the positive suction head by low-

ering the pump or increasing the suction

pipe and fittings size.

2.

Sub-cool the suction piping at the inlet to

lower the temperature of liquid that is en-

tering the pump.

3.

Pressurize the suction vessel.

The pump and driver are not aligned.

Realign the pump and driver.

The suction inlet is not submersed

deep enough.

If the inlet cannot be lowered or if the problem per-

sists after the inlet is lowered, then chain a board

to the suction pipe. The board will be drawn into

the eddies and smother the vortex.

The casing is distorted due to exces-

sive strains from the suction and dis-

charge piping.

Check the alignment. Examine the pump for rub-

bing between the impeller and the casing. Replace

damaged parts and redo the piping.

The element turns

hard or has a rub.

The shaft is bent.

Straighten the shaft or replace it if necessary.

The running clearances between the

wear rings are incorrect.

Check for the proper clearances. Replace the cas-

ing or impeller wear rings if necessary.

There is excessive pipe strain on the

pump casing.

Relieve the strain and check the alignment. Con-

sult ITT if necessary.

There is excessive runout on the shaft

or impeller rings.

Inspect the rotating element and bearings. Replace

worn or damaged parts as necessary.

There is dirt in the casing ring or be-

tween the impeller and casing wear

rings.

Clean and inspect the wear rings. Replace worn or

damaged parts as necessary. Isolate and relieve

the source of dirt.

7.1 Troubleshooting

Model 3410 Installation, Operation, and Maintenance Manual

77

Содержание GOULDS PUMPS 3410

Страница 1: ...Installation Operation and Maintenance Manual Model 3410 ...

Страница 2: ......