Thermal/Mechanical Design Guide

29

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

4.6

Environmental Requirements

Design, including materials, shall be consistent with the manufacture of units that meet

the following environmental reference points.

The reliability targets in this chapter are based on the expected field use environment

for these products. The test sequence for new sockets will be developed using the

knowledge-based reliability evaluation methodology, which is acceleration factor

dependent. A simplified process flow of this methodology can be seen in

Figure 4-1

.

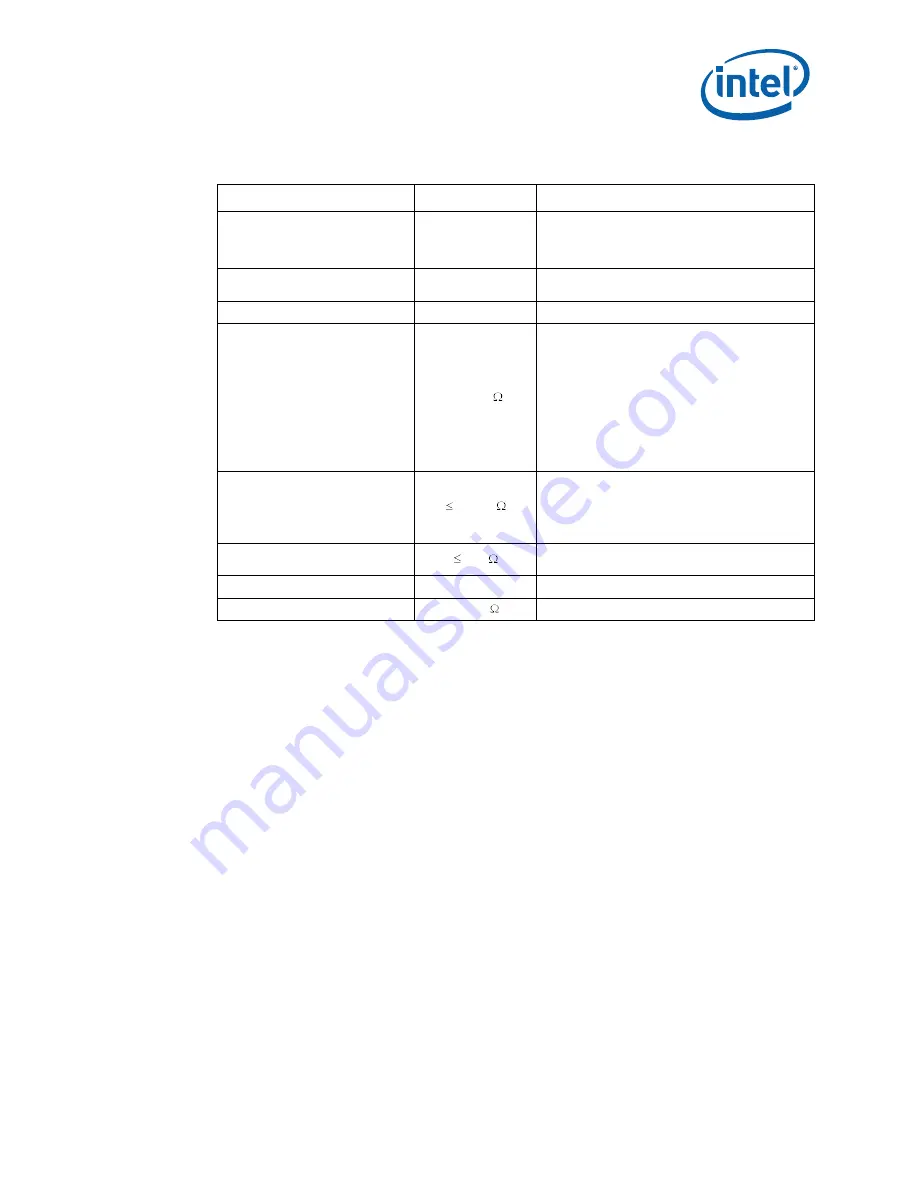

Table 4-4.

Electrical Requirements for LGA1366 Socket

Parameter

Value

Comment

Mated loop inductance, Loop

<3.9nH

The inductance calculated for two contacts,

considering one forward conductor and one return

conductor. These values must be satisfied at the

worst-case height of the socket.

Mated partial mutual inductance, L

NA

The inductance on a contact due to any single

neighboring contact.

Maximum mutual capacitance, C.

<1 pF

The capacitance between two contacts

Socket Average Contact Resistance

(EOL)

15.2 m

The socket average contact resistance target is

derived from average of every chain contact

resistance for each part used in testing, with a

chain contact resistance defined as the resistance

of each chain minus resistance of shorting bars

divided by number of lands in the daisy chain.

The specification listed is at room temperature

and has to be satisfied at all time.

Socket Contact Resistance: The resistance of

the socket contact, solderball, and interface

resistance to the interposer land.

Max Individual Contact Resistance

(EOL)

100 m

The specification listed is at room temperature

and has to be satisfied at all time.

Socket Contact Resistance: The resistance of

the socket contact, solderball, and interface

resistance to the interposer land; gaps included.

Bulk Resistance Increase

3 m

The bulk resistance increase per contact from

24 °C to 107 °C

Dielectric Withstand Voltage

360 Volts RMS

Insulation Resistance

800 M

Содержание X5550 - Quad Core Xeon

Страница 8: ...8 Thermal Mechanical Design Guide ...

Страница 12: ...Introduction 12 Thermal Mechanical Design Guide ...

Страница 24: ...Independent Loading Mechanism ILM 24 Thermal Mechanical Design Guide Figure 3 3 ILM Assembly ...

Страница 26: ...Independent Loading Mechanism ILM 26 Thermal Mechanical Design Guide ...

Страница 48: ...Component Suppliers 48 Thermal Mechanical Design Guide ...

Страница 50: ...Mechanical Drawings 50 Thermal Mechanical Design Guide Figure B 1 Board Keepin Keepout Zones Sheet 1 of 4 ...

Страница 51: ...Thermal Mechanical Design Guide 51 Mechanical Drawings Figure B 2 Board Keepin Keepout Zones Sheet 2 of 4 ...

Страница 52: ...Mechanical Drawings 52 Thermal Mechanical Design Guide Figure B 3 Board Keepin Keepout Zones Sheet 3 of 4 ...

Страница 53: ...Thermal Mechanical Design Guide 53 Mechanical Drawings Figure B 4 Board Keepin Keepout Zones Sheet 4 of 4 ...

Страница 54: ...Mechanical Drawings 54 Thermal Mechanical Design Guide Figure B 5 1U Reference Heatsink Assembly Sheet 1 of 2 ...

Страница 55: ...Thermal Mechanical Design Guide 55 Mechanical Drawings Figure B 6 1U Reference Heatsink Assembly Sheet 2 of 2 ...

Страница 58: ...Mechanical Drawings 58 Thermal Mechanical Design Guide Figure B 9 Heatsink Shoulder Screw 1U 2U and Tower ...

Страница 59: ...Thermal Mechanical Design Guide 59 Mechanical Drawings Figure B 10 Heatsink Compression Spring 1U 2U and Tower ...

Страница 60: ...Mechanical Drawings 60 Thermal Mechanical Design Guide Figure B 11 Heatsink Retaining Ring 1U 2U and Tower ...

Страница 61: ...Thermal Mechanical Design Guide 61 Mechanical Drawings Figure B 12 Heatsink Load Cup 1U 2U and Tower ...

Страница 82: ...Mechanical Drawings 82 Thermal Mechanical Design Guide ...

Страница 88: ...Socket Mechanical Drawings 88 Thermal Mechanical Design Guide ...

Страница 95: ...Thermal Mechanical Design Guide 95 Embedded Thermal Solutions Figure E 5 UP ATCA Heat Sink Drawing ...

Страница 102: ...Processor Installation Tool 102 Thermal Mechanical Design Guide Figure F 1 Processor Installation Tool ...