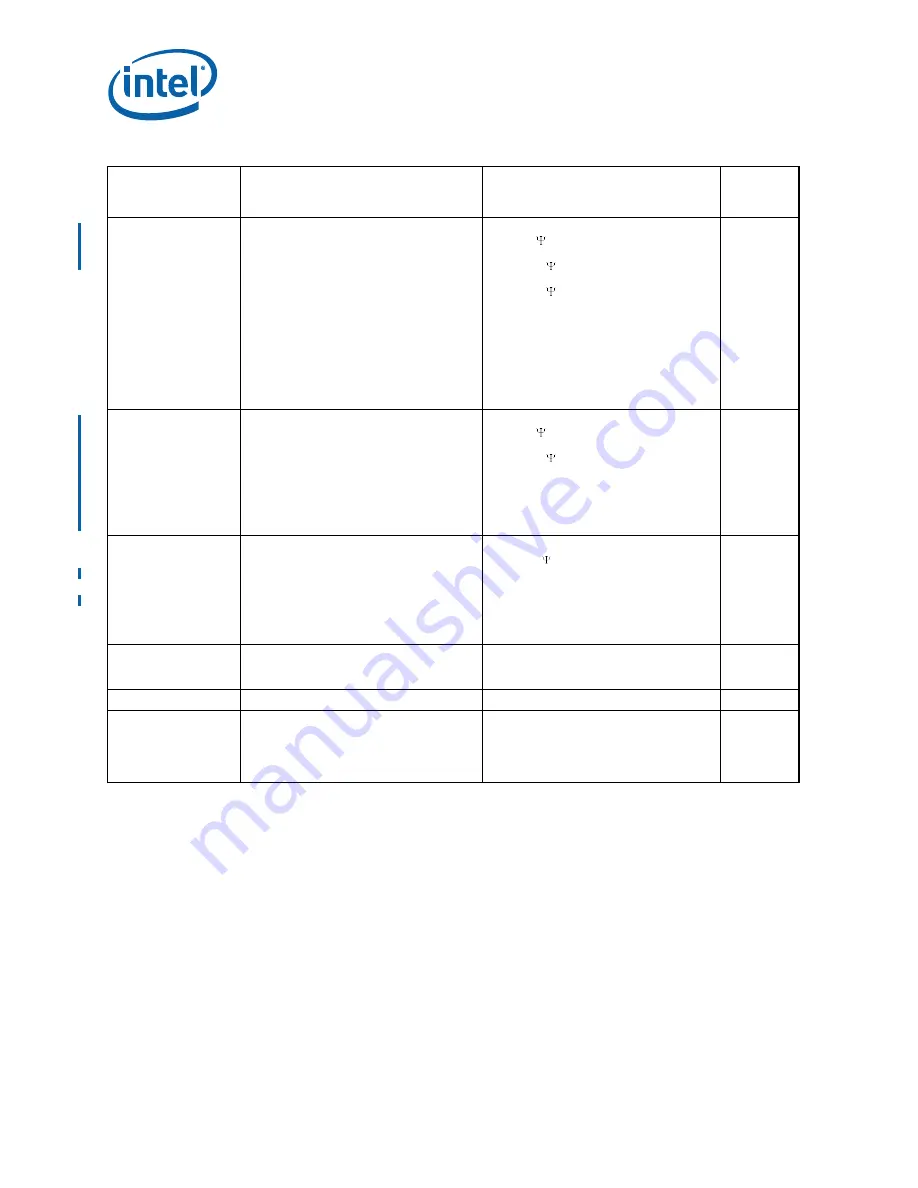

Quality and Reliability Requirements

42

Thermal/Mechanical Design Guide

8a) Thermal

Performance for

Intel® Xeon®

Processor 5500 Series

Using 1U heatsink and 1U airflow from

Table 5-1

:

1) TTV @ 95W (Profile B), Note 1.

Using 2U heatsink and 2U airflow from

Table 5-1

:

2) TTV @ 95W (Profile A), Note 1.

3) TTV @ 80W.

4) TTV @ 60W.

Using Tower heatsink and Tower airflow

from

Table 5-1

:

5) TTV @ 130W, Note 1.

6) TTV @ 95W (Profile A).

7) TTV @ 80W.

8) TTV @ 60W.

As verified in wind tunnel:

1) mean

CA

+ 3s + offset not to exceed

Table 5-1

value for 95W in 1U.

2-4) mean

CA

+ 3s + offset not to exceed

Table 5-1

value for 2U.

5-8) mean

CA

+ 3s + offset not to exceed

Table 5-1

value for Tower.

5 heatsinks

X 8 tests by

supplier.

Note 1: 30

heatsinks X

3 tests by

Intel.

8b) Thermal

Performance for

Intel® Xeon®

Processor 5600 Series

Using 1U heatsink and 1U airflow from

Table 5-2

:

1) TTV @ 95W (Profile B), Note 1.

Using 2U heatsink and 2U airflow from

Table 5-2

:

2) TTV @ 130W, Note 1.

3) TTV @ 95W (Profile A).

4) TTV @ 80W.

5) TTV @ 60W.

As verified in wind tunnel:

1) mean

CA

+ 3s + offset not to exceed

Table 5-2

value for 95W in 1U.

2-5) mean

CA

+ 3s + offset not to exceed

Table 5-2

value for 2U.

Thermal

Test data

re-assessed

from Intel®

Xeon®

Processor

5500 Series

Qualification

9) Thermal Cycling

Required for heatpipe designs.

Temperature range at pipe in heatsink

assembly: -25C to +100C for 500 cycles.

Cycle time is 30 minutes per full cycle,

divided into half cycle in hot zone and half

in cold zone, with minimum 1min soak at

each temperature extreme for each cycle.

See

Figure 6-1

for example profile.

As verified in wind tunnel:

•

Mean

CA

+ 3s + offset not to exceed

value in

Table 5-1

and

Table 5-2

.

•

Pressure drop not to exceed value in

Table 5-1

and

Table 5-2

.

15

10) Heat Pipe Burst

Continuously raise oven temperature and

record the burst/leak temperatures of fully

assembled heatsinks

No failures at minimum of 300C @ 20

minutes

32 pipes

11) Heatsink Mass

Design Target < 500 g

All samples < 550 g

30

12) Heatsink Load

Design Targets:

0.062" board = 38.7 ± 7.2 lbf (Fmin =

31.5 lbf).

0.100" board = 51.4 ± 7.9 lbf (Fmax =

59.3 lbf).

No samples < 30 lbf on 0.062" board.

5 highest load samples (from 0.062" test)

< 60 lbf on 0.100" board

30

Table 6-1.

Heatsink Test Conditions and Qualification Criteria (Sheet 2 of 2)

Assessment

Test Condition

Qualification Criteria

Min

Sample

Size

Содержание X5550 - Quad Core Xeon

Страница 8: ...8 Thermal Mechanical Design Guide ...

Страница 12: ...Introduction 12 Thermal Mechanical Design Guide ...

Страница 24: ...Independent Loading Mechanism ILM 24 Thermal Mechanical Design Guide Figure 3 3 ILM Assembly ...

Страница 26: ...Independent Loading Mechanism ILM 26 Thermal Mechanical Design Guide ...

Страница 48: ...Component Suppliers 48 Thermal Mechanical Design Guide ...

Страница 50: ...Mechanical Drawings 50 Thermal Mechanical Design Guide Figure B 1 Board Keepin Keepout Zones Sheet 1 of 4 ...

Страница 51: ...Thermal Mechanical Design Guide 51 Mechanical Drawings Figure B 2 Board Keepin Keepout Zones Sheet 2 of 4 ...

Страница 52: ...Mechanical Drawings 52 Thermal Mechanical Design Guide Figure B 3 Board Keepin Keepout Zones Sheet 3 of 4 ...

Страница 53: ...Thermal Mechanical Design Guide 53 Mechanical Drawings Figure B 4 Board Keepin Keepout Zones Sheet 4 of 4 ...

Страница 54: ...Mechanical Drawings 54 Thermal Mechanical Design Guide Figure B 5 1U Reference Heatsink Assembly Sheet 1 of 2 ...

Страница 55: ...Thermal Mechanical Design Guide 55 Mechanical Drawings Figure B 6 1U Reference Heatsink Assembly Sheet 2 of 2 ...

Страница 58: ...Mechanical Drawings 58 Thermal Mechanical Design Guide Figure B 9 Heatsink Shoulder Screw 1U 2U and Tower ...

Страница 59: ...Thermal Mechanical Design Guide 59 Mechanical Drawings Figure B 10 Heatsink Compression Spring 1U 2U and Tower ...

Страница 60: ...Mechanical Drawings 60 Thermal Mechanical Design Guide Figure B 11 Heatsink Retaining Ring 1U 2U and Tower ...

Страница 61: ...Thermal Mechanical Design Guide 61 Mechanical Drawings Figure B 12 Heatsink Load Cup 1U 2U and Tower ...

Страница 82: ...Mechanical Drawings 82 Thermal Mechanical Design Guide ...

Страница 88: ...Socket Mechanical Drawings 88 Thermal Mechanical Design Guide ...

Страница 95: ...Thermal Mechanical Design Guide 95 Embedded Thermal Solutions Figure E 5 UP ATCA Heat Sink Drawing ...

Страница 102: ...Processor Installation Tool 102 Thermal Mechanical Design Guide Figure F 1 Processor Installation Tool ...