Additional information

27 of 31

Revision 4.0

2021-10-11

Recommendations for board assembly of Infineon transistor outline

type packages

Inspection

6.2

X-ray solder joint inspection

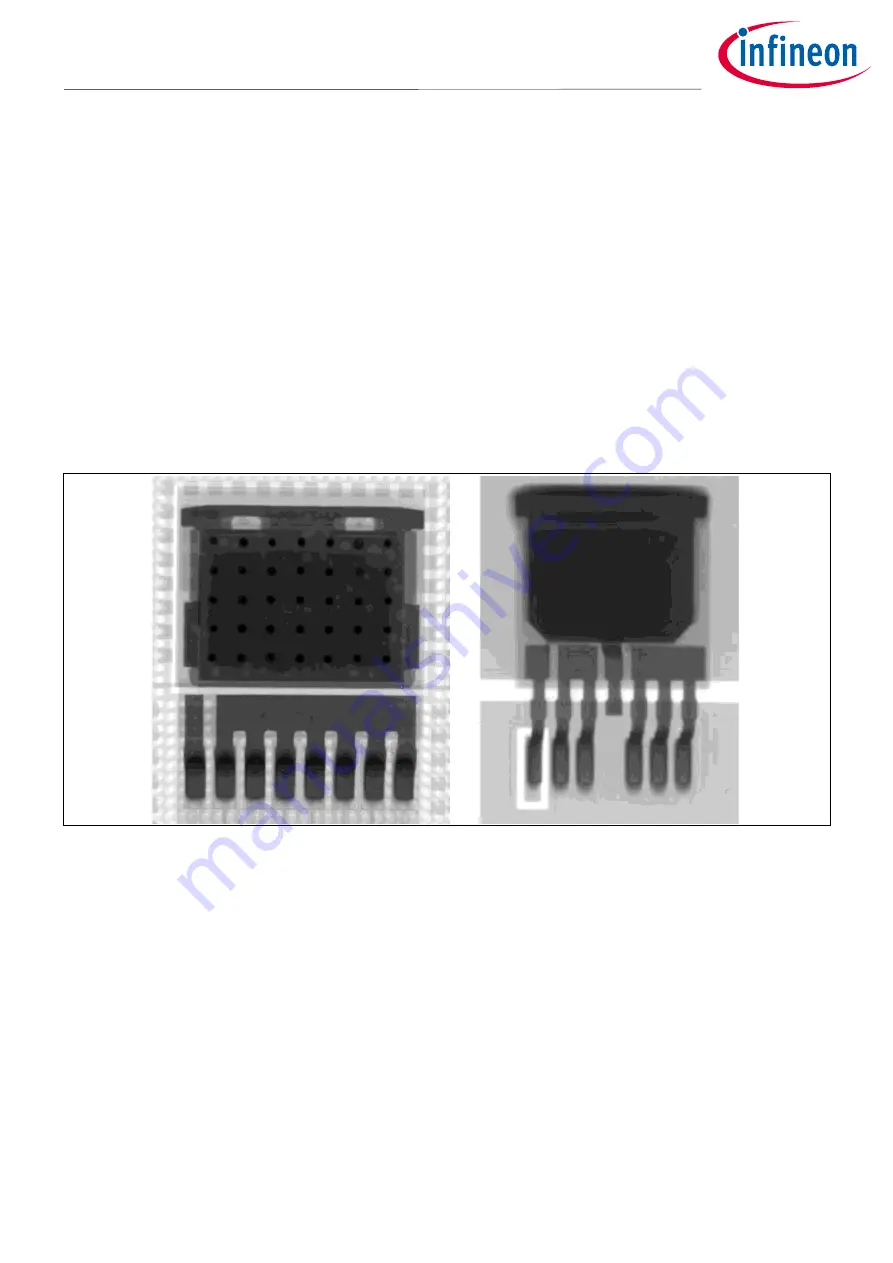

Automated X-ray inspection (AXI) systems are appropriate for efficient inline control of component parts that

cannot be inspected properly by optical systems (such as exposed pads). AXI systems are available as 2D and

3D solutions. They usually consist of an X-ray camera and the hardware and software needed for inspection,

controlling, analyzing, and data transferring routines. These reliable systems enable the user to detect

soldering defects such as poor soldering, bridging, voiding, and missing parts. However, other defects such as

broken solder joints are not easily detectable by X-ray.

shows typical X-ray photographs of HSOG-8 and TO263-7 SMD components. The top and inner layers

of the boards as well as vias in the pad are visible. Large exposed pads may tend to increased voiding because

they do not provide a sufficient ratio between volume and surface necessary for proper outgassing of the

organic paste compounds during reflow. Generally, the extent of voiding depends on the board pad size, the via

and stencil layout, the solder paste, and the reflow profile. For thermal evaluations, the entire thermal path

must be considered as well as all boundary conditions such as the application environment or the electrical use

of the component

Figure 21

Typical X-ray image of a soldered HSOG-8 (left) and of a TO263-7 SMD package (right).