This document is property of NIIGATA POWER SYSTEMS CO., LTD. It must be neither reproduced nor communicated nor published without permission.

SECTION

4

- DISASSEMBLY AND REASSEMBLY

4.10

COOLING AND LUBRICATING OIL PUMP

4-10-01

4.10 COOLING AND LUBRICATING OIL PUMPS

Generally both the cooling water pump and lubricating are engine driven.

(Operations are available, however,for separate pumps for both circuits in those

instances, refer to the appropriate service manuals provided with the pumps).

This section describes the procedure for inspecting and/or rebuilding the engine

-driven pumps.

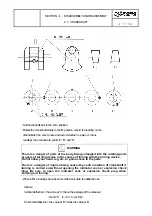

4.10.1 Cooling Water Pumps

The pump is driven by the timing gear train through an input gear

①

.

The impeller is keyed to the shaft (a taper fit),and secured by a retaining nut

⑧

.

The shaft runs on two ball bearings

⑪

.Two seals are use;(a) a mechanical

face-type seal to prevent coolant leakage into the oil into the compartment

⑤

and (b),a lip-type oil seal to prevent oil transfer into the coolant

⑥

.

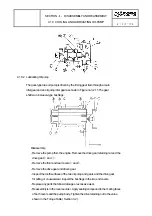

To remove and disassemble the pump:

- Drain the cooling system and remove the pump from the engine.

- Remove the impeller housing

④

- Loosen the impeller retaining nut and remove the impeller,withdrawing it

carefully so that the mechanical seal and shaft are not damaged.

- Remove the nut

⑧

that secures the drive gear to the shaft. Remove the gear.

- Remove the shaft and bearings from the housing.(The bearings are positioned by

snap rings that must be removed).

- Inspect the impeller and housing for signs cavitation erosion - if the damage

is severe,new parts should be installed. Measure the clearance between the

impeller and the liner ring (refer to Section 3.2)and replace pitting or

other damage.(New bearings should generally be installed whenever the water

pump is disassembled unless they have few hours of use).

- Clean all parts and rebuild the pump in the reverse order of disassembly.

A new mechanical seal, oil seal and ball bearings should be used.

Apply of the shaft and bearings, but be careful not to get oil onto the faces

of the mechanical seal.

- Use LOCKTITE 242 or equivalent on the impeller and drive gear retaining nuts.

Tighten the nuts ti the values given in the Toque Table(Section 3.2)

Содержание NIIGATA MG(L)26HLX

Страница 1: ...DOCUMENT No 2086X 50000D REMARKS 12 2021 INSTRUCTION MANUAL FOR NIIGATA DIESEL MODEL MG L 26HLX...

Страница 2: ......

Страница 34: ......

Страница 38: ......

Страница 40: ......

Страница 60: ......

Страница 66: ......

Страница 68: ......

Страница 80: ......

Страница 82: ......

Страница 86: ......

Страница 88: ......

Страница 94: ......

Страница 107: ......

Страница 108: ......

Страница 110: ......

Страница 130: ......

Страница 132: ......

Страница 170: ......

Страница 174: ......

Страница 186: ......

Страница 188: ......

Страница 192: ......