This document is property of NIIGATA POWER SYSTEMS CO., LTD. It must be neither reproduced nor communicated nor published without permission.

SECTION

4

- DISASSEMBLY AND REASSEMBLY

4.4 FUEL INJECTION VALVES AND FUEL INJECTION

PUMPS

4-4-01

4.4 FUEL INJECTION VALVE AND FUEL INJECTION PUMP

4.4.1 Injection valve

WARNING

There is a danger of injuries caused if high-pressure oil droplets come in direct

contact with your skins when conducting the injection test of fuel injection pump.

Never allow your body to gain access to the range covered by oil droplets.

In case where high-pressure oil droplets have come into your body through the

skin, then it is necessary to undergo forthwith specialist's diagnosis and surgical

treatment.

CAUTION

When using hydraulic tools or when conducting the fuel injection valve injection

test, high- pressure fluid will gush out , leading to the danger of injuries.

Never allow your body to gain access to the range covered by oil droplets.

In case where high-pressure oil droplets have come into your body through the

skin, then it is necessary to undergo forthwith specialist's diagnosis and surgical

treatment.

Apply hydraulic pressure only after making sure that joints are securely connected.

Be sure to put on safety goggles in carrying out the following items of work being

in danger of injury to eyes.

・

When handling fuel oil

・

In course of fuel injection valve injection test

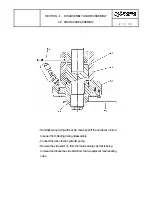

Each fuel injection valve consists of a forged steel body, an injection

nozzle, and an injector pressure regulating mechanism. The diameter, number

of spray holes, and angle of the holes in the nozzle are selected to provide

optimum performance for the particular rating being used. For those

applications where heavy fuel is used, the nozzles are water-cooled to reduce

the rate of carbon buildup on the tips.

The injection valves should be checked every 1500 hours for spray pattern,

・

leakage, and opening pressure. Procedures are give below.

Special tools supplied

Tools are supplied for removing the injector valves,cleaning the nozzle tips,

and for pressure/leakage testing of the valves.

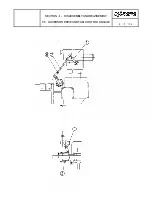

Injection valve Removal

- Remove the fuel inlet pipe

①

.

- Remove the injection valve retainer

②

.

- Install the puller (Tool “A”) and lift injector from its bore.

Содержание NIIGATA MG(L)26HLX

Страница 1: ...DOCUMENT No 2086X 50000D REMARKS 12 2021 INSTRUCTION MANUAL FOR NIIGATA DIESEL MODEL MG L 26HLX...

Страница 2: ......

Страница 34: ......

Страница 38: ......

Страница 40: ......

Страница 60: ......

Страница 66: ......

Страница 68: ......

Страница 80: ......

Страница 82: ......

Страница 86: ......

Страница 88: ......

Страница 94: ......

Страница 107: ......

Страница 108: ......

Страница 110: ......

Страница 130: ......

Страница 132: ......

Страница 170: ......

Страница 174: ......

Страница 186: ......

Страница 188: ......

Страница 192: ......