This document is property of NIIGATA POWER SYSTEMS CO., LTD. It must be neither reproduced nor communicated nor published without permission.

SECTION

4

- DISASSEMBLY AND REASSEMBLY

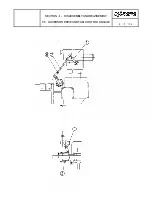

4.3 CYLINDER LINER

4-3-03

4.3.5 Inspection of liner after removal from engine block

Scale Deposits in coolant area

- If scale formation on the OD of the liner exceeds 0.5 mm, it should be

removed by wire brushing. In addition, when the engine is put back into

service, a descaling agent should be added to the cooling system to remove

scale from the rest of the system. DO NOT use acid solutions for descaling.

Dye Penetration Test

- Cylinder liner flanges should be checked for cracking by using a dye

penetrant. A new liner should be installed if any cracks are found. Make

sure that the liners are clean before using the dry penetrant, otherwise

false indications could occur.

4.3.6 Reassembly

- Paint SDC 402 COAT or equivalent anti-rust epoxy paint on the jacket side

surfaces of liner.

- Install new liner o-rings.

- Coat the upper and lower bores in the block with a silicon compound.

Содержание NIIGATA MG(L)26HLX

Страница 1: ...DOCUMENT No 2086X 50000D REMARKS 12 2021 INSTRUCTION MANUAL FOR NIIGATA DIESEL MODEL MG L 26HLX...

Страница 2: ......

Страница 34: ......

Страница 38: ......

Страница 40: ......

Страница 60: ......

Страница 66: ......

Страница 68: ......

Страница 80: ......

Страница 82: ......

Страница 86: ......

Страница 88: ......

Страница 94: ......

Страница 107: ......

Страница 108: ......

Страница 110: ......

Страница 130: ......

Страница 132: ......

Страница 170: ......

Страница 174: ......

Страница 186: ......

Страница 188: ......

Страница 192: ......