P

P

a

a

g

g

e

e

2

2

4

4

Under no circumstances should bearing cones or cups be hammered

into position.

For torque settings of fasteners and shaft rolling torque, see section 5.2.

4.1

Disassembly.

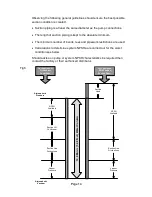

4.1.1 Front Cover and Rotor Removal

See Fig 10.

-

Follow recommended Shutdown Procedure, referring to section 3.5.

-

Gradually loosen front cover retaining nuts (36). Care should be taken

as residual product and pressure may still be present in the pump head.

As the dome nuts are loosened this will vent to atmosphere.

-

Remove dome nuts (36).

-

Remove front cover (38), using lever slots where necessary, continue

and remove the front cover O-ring (39) from rotorcase (40).

-

Remove rotor retainer’s (35) using socket (58) provided.

Note: The socket (58) should always be used. The use of other tools may

damage the retainer.

-

Remove retainer O-ring (34).

-

Remove rotors (41) from shafts (9 and 10 – not shown), taking care not

to damage the product seal components. Where viscous products are

employed, a tool is available utilising the three M6 tapped holes, to aid

in the removal of the rotors (41). Contact Wright Flow Technologies

Limited or an authorised distributor for details.

-

Remove O-ring (25 – not shown) from shafts (9 and 10 – not shown).

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Содержание Wright Flow Technologies RTP Series

Страница 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Страница 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Страница 51: ...P Pa ag ge e 5 50 0 B B 100 mm or 4 PORT 80 mm or 3 PORT 5 5 RTP30 Foundation Dimensions Stub Shaft Drive...

Страница 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Страница 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...