P

P

a

a

g

g

e

e

1

1

6

6

3.4

Start-Up Procedure.

-

Check that all piping and associated equipment are clean and free from

debris and that all pipe connections are secure and leak free.

-

For pumps installed with flushed product seals check that all auxiliary

services are in place and connected and provide sufficient flow and

pressure for flushing purposes, refer to product seal section 4.3.

-

Refer to section 5.3 for lubricant capacities and grades.

As standard, the pump is shipped with grease lubricant unless otherwise

specified. The oil filled pumps differ in gearbox construction where

breather, drain plug, and sight glasses are fitted.

-

If an external relief valve is incorporated in the system check that it is set

correctly. For start-up purposes, it is considered a good practice to set the

relief valve lower than the system design pressure. On completion of start

up the relief valve should be reset to the required setting for the

application. The required setting should never exceed the lower of either

the pumps maximum pressure rating or the system design pressure. For

setting integral relief valves, refer to sections 3.8.

-

Ensure both suction and discharge valves are fully open, and pipework is

free from all obstructions. RTP

TM

pumps are of the positive displacement

type and should therefore never be operated against a closed valve as this

would result in pressure overload, resulting in damage to the pump and

possibly the system.

-

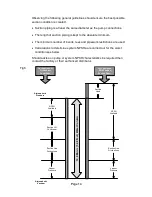

Ensure rotation of the drive shaft is correct for the direction of flow

required, see Fig 7.

Fig 7 Direction of Rotation

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Содержание Wright Flow Technologies RTP Series

Страница 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Страница 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Страница 51: ...P Pa ag ge e 5 50 0 B B 100 mm or 4 PORT 80 mm or 3 PORT 5 5 RTP30 Foundation Dimensions Stub Shaft Drive...

Страница 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Страница 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...