P

P

a

a

g

g

e

e

3

3

1

1

They should also not be tightened to the correct torque at this

point, as an adjustment to the timing may still be required

.

-

Install rear bearing (19).

-

Install the shaft assemblies into the gearbox (16) so that the cone and

cup halves of the front bearing (24) are now one unit.

-

Assemble the endplate by installing O-ring (3) and place a nominal

amount (0.05 mm) of shim (73) under the rear bearing cups (19).

Do not

install the rear lip seal (11) until the bearing pre-load has been set.

The lips may give a false rolling torque reading as well as

increasing the risk of damage during assembly.

-

Install endplate assembly onto the gearbox (16) locating on the dowel

(60).

4.2.4 Timing.

-

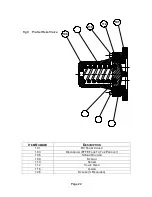

Rotate the shafts (9 and 10) so as to position the gaps made by the

missing splines, in the vertically uppermost position, See Fig 17.

F

F

i

i

g

g

1

1

6

6

S

S

h

h

a

a

f

f

t

t

A

A

s

s

s

s

e

e

m

m

b

b

l

l

y

y

.

.

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Содержание Wright Flow Technologies RTP Series

Страница 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Страница 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Страница 51: ...P Pa ag ge e 5 50 0 B B 100 mm or 4 PORT 80 mm or 3 PORT 5 5 RTP30 Foundation Dimensions Stub Shaft Drive...

Страница 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Страница 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...