P

P

a

a

g

g

e

e

2

2

3

3

D

ANGER

Under no circumstances should any attempt be made to dismantle a

pressure relief valve which has not had the spring pressure relieved

(where applicable) or is mounted on a pump that is operating. Serious

personal injury or pump damage may occur.

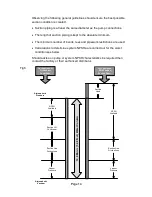

4.0

RTP

TM

Pump Dismantling and Assembly.

Before undertaking any work on the pump the Shutdown Procedure should be

followed in section 3.5, and site safety practices must be observed.

While dismantling or assembling the pump it is essential to ensure that the

pump and/or components are secured to provide adequate stability.

Large pump components or assemblies should be lifted using suitable

devices. Use threaded holes for attaching lifting eyes where appropriate.

During dismantling or before assembly all components should be inspected for

fit, wear, and damage. If worn or damaged the components should be

replaced before re-assembly.

The position of all parts should be identified as they are removed to ensure

they are reinstalled in the same position.

Lip-seals and O-rings are incorporated within the assembly. Regular

inspection and correct maintenance of these items will ensure that the

lubrication is sustained and the pump maximum working life is achieved. To

ensure this, it is extremely important that care is taken when removing and

installing new O-rings and lip-seals. When removing and replacing lip-seals

ensure that the location bore for the outside diameter and the seat for the back

of the lip-seal is not damaged as this may create a leakage path.

When removing Lip-seals or O-rings care should be taken to avoid

cutting or tearing the sealing faces as they pass over splines, threads or

other potentially sharp or abrasive edges

. All lip-seals and O-rings should

be carefully examined and if damaged in any way, replaced on assembly.

All O-rings and sealing lips of Lip-seals should be lightly lubricated with a

suitable lubricant (silicon grease, etc.) before installing.

Prior to assembly, ensure all parts are clean and free from burrs or damage.

When a vice is to be used, it should have protective jaws to avoid damage to

components. Do not apply undue force to install or position components.

All fasteners are required to be tightened to the required torque setting during

assembly, refer to section 5.2.

Bearing cones may be pressed into position providing the proper equipment

and procedures are employed to prevent component damage.

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Содержание Wright Flow Technologies RTP Series

Страница 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

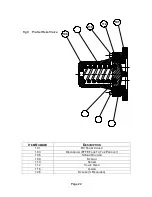

Страница 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Страница 51: ...P Pa ag ge e 5 50 0 B B 100 mm or 4 PORT 80 mm or 3 PORT 5 5 RTP30 Foundation Dimensions Stub Shaft Drive...

Страница 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Страница 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...