5. Start-Up/Operation - Non-Contact Sensor Operation

76

10260S HercuLine® Actuator Installation, Operation and Maintenance Manual

Revision 5

7/07

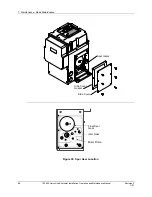

Non-Contact Sensor Operation

The non-contact sensor (NCS) is magnetically coupled to the output shaft of the actuator so that the sensor

detects shaft position. The sensor is adjusted at the factory and under normal conditions, the NCS requires

no adjustment. A simple check can verify that the sensor working properly and that it is in adjustment.

Verification of the NCS output is performed by setting the drive motor to its zero, midpoint and 100%

positions and observing the output voltage of the non-contact sensor PWA. The actuator has a feature that

allows the NCS output voltage to be read from the local display.

Step

Action

1

Drive the motor to 50% position.

2

Press SET UP key on the keyboard until the display reads CAL POSOUT.

Press FUNCTION key until the display reads DIS CALPOS.

Press the

or

keys until the display reads BEGN CALPOS.

Press the FUNCTION key.

Upper

Display

=

n.nnn

(Output voltage of the non-contact sensor)

Lower Display

=

POSOUT

3

The display should read 2.500 + or – 0.012 Volts.

4

Press DISPLAY key and then drive the motor to zero position. Repeat Step 2.

The display should read 1.600 + or – 0.060 Volts.

5

Press DISPLAY key and then drive the motor to 100% position. Repeat Step 2.

The display should read 3.400 + or – 0.060 Volts

6

If the NCS needs adjustment, refer to the “Calibrate Non-Contact Sensor” procedure in Table

27 in Section 4.

Remote Setpoint Operation

The 10260S actuator can be set up to receive a digital input from a remote source. The actuator uses

RS485 communications that supports digital Modbus RTU protocol. Press the SET UP key to select the

Input set up group. Change the Input Type to Remote Setpoint (R_SP). Make the necessary connections to

terminals 33, 34 and 35 on the actuator terminal block. See Figure 23. Communicaton parameters should

be set to the same values as the host device. The actuator communication parameters are accessed in the

Communications Set Up group.

There are some restrictions to actuator operation when remote setpoint input is active. In order to provide a

bumpless transfer when switching from one input signal type to remote setpoint, the actuator will use the

last known analog input value as its setpoint when swtiching to remote setpoint input operation. The

actuator motor can only be set to full span (90 degrees of rotation). It cannot be set to a reduced range of

rotation. No input filtering is active on the input signal to the actuator.

Содержание HercuLine 10260S

Страница 10: ......

Страница 94: ......

Страница 121: ......

Страница 122: ...Honeywell Field Solutions Honeywell Inc 512 Virginia Drive Fort Washington PA 19034 ...