HAMWORTHY HEATING LTD

20

SPETISBURY

500001118/C

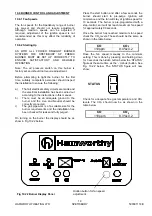

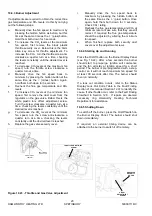

10.6.3 Burner Adjustment

If adjustments are required to obtain the correct flue

gas temperature and CO

2

levels, do this by carrying

out the following steps;

a.

Manually drive the fan speed to maximum by

pressing the hidden button as before, but this

time at the same time as the ‘+’ (plus) button.

Hold them both down for 3 seconds.

b.

To increase the CO

2

levels at the maximum

fan speed, first remove the black plastic

throttle security cover. Below this is the 3mm

Allen key screw for throttle adjustment. To

increase the CO

2

, turn the throttle screw anti-

clockwise a quarter turn at a time, checking

the levels constantly until the desired level is

reached.

c.

To decrease CO

2

levels at the maximum fan

speed, turn the throttle screw clockwise a

quarter turn at a time.

d.

Manually drive the fan speed back to

minimum by pressing the hidden button at the

same time as the ‘-’ (minus) button. Again,

hold them both down for 3 seconds.

e.

Recheck the flue gas temperature and CO

2

levels

f.

To increase CO

2

levels at the minimum fan

speed, first remove the dust cover from the

regulator on the gas valve. Below this is the

white plastic torx offset adjustment screw.

Turn the screw clockwise a quarter turn at a

time, checking the levels constantly until the

desired level is reached.

g.

To decrease the CO

2

levels at the minimum

fan speed, turn the screw anti-clockwise a

quarter turn at a time, checking the levels

constantly until the desired level is reached.

h.

Replace the gas valve security cover.

i.

Manually drive the fan speed back to

maximum by pressing the hidden button at

the same time as the ‘+’ (plus) button. Once

again, hold them both down for 3 seconds.

Check CO

2

/ rating.

j.

Recheck the flue gas temperature and CO

2

at

minimum rate to make sure that they are still

correct. If required the flue gas temperature

should be adjusted by altering the minimum

fan speed.

k.

When finished, replace both security dust

covers over the adjustment screws.

10.6.4 Starting Up and Running

Press the On/Off button on the Burner Display Panel

(see Fig. 10.22). After a few seconds the burner

should start to pre-purge. Ignition will commence

and the fan will stay at ignition speed for a short

period. The burner is pre-programmed with a step-

control, so it will not reach maximum fan speed for

at least 90 seconds after this. The burner should

then run normally.

If a lock out condition occurs, refer to the Status

Display Lock Out Code Table in the Fault Finding

Section of this manual (Section 12.0) to identify the

cause. If other faults occur, refer to the Fault Finding

Flowchart in Section 12.0. If repairs are deemed

necessary ring Hamworthy Heating Technical

Department for assistance.

10.6.5 Shutting Down

To switch off the burner, press the On/Off switch on

the Burner Display Panel. The burner should shut

down immediately.

If required, an external timing device can be

attached to the burner to switch it off remotely.

POSITION OF

VENTURI

POSITION OF

GAS VALVE

THROTTLE ADJUSTMENT

SCREW

OFFSET

ADJUSTMENT

SCREW

GAS VALVE

SECURITY

COVER

Figure 10.23 - Throttle and Gas Valve Adjustment

Содержание Spetisbury

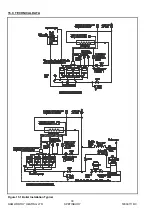

Страница 30: ...HAMWORTHY HEATING LTD 24 SPETISBURY 500001118 C Figure 12 2 Fault Finding Flowchart...

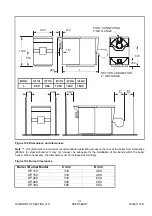

Страница 36: ...HAMWORTHY HEATING LTD 30 SPETISBURY 500001118 C Figure 15 1 Boiler Installation Typical 15 0 TECHNICAL DATA...

Страница 42: ...HAMWORTHY HEATING LTD 36 SPETISBURY 500001118 C NOTES...

Страница 43: ...Notes...