HAMWORTHY HEATING LTD

15

SPETISBURY

500001118/C

i.

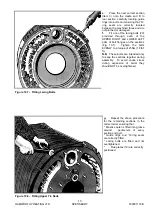

Fit thermostat pocket (18) in top and bottom

of front section, and ¾" BSP drain plug or cock (not

supplied) to bottom of front section (See Fig. 14.3

for fitting instruction).

j.

Fit heating flow pipe elbow (28) to top of rear

section, note correct orientation.

Figure 10.11 – Outflow Pipework Orientation

k.

Fit water distribution tube (11), holes

uppermost, into the return connection at bottom of

rear section. (Note: Not required on SP 110, 150

and 220.

l.

On completion of assembly, the heat

exchanger should be hydraulically pressure tested

to 1.5 times the maximum system pressure for 30

minutes (BS779 - 1989, Amendment 1 - 1993).

10.4 Assembly of Boiler

.

Further to assembly of the sections, proceed as

follows (refer to Fig. 14.1):

a.

Locate and fit the flue collector box (23) to the

upper part of the rear casting using the studs, nuts

and gaskets (22) provided. The rear access doors

(25,26) will need to be loosened to allow correct

fitting of gaskets.

b.

On SP 110, SP 150 and SP 220 models,

locate and fit the burner mounting plate (13)

ensuring that the pads of insulation are packed into

the burner aperture and that the fibre board gasket

(12) is in position. Carefully cut a hole through both

the fibre pads and board, large enough to accept the

burner blast tube.

Note!

Burner mounting plate

NOT

required on SP 280 and SP 340 models.

c.

Locate the foil covered insulation wrap which

comprises a front blanket, a rear blanket and

lengths of straight wrap. Position the front and rear

blankets on the boiler so that the cut outs align with

the appropriate items, i.e. burner mounting plate,

thermostat pocket, flue collector and return

connection. Mould the excess wrap backwards

around the edges of the boiler sections and tape to

secure. Position the straight wraps over the boiler

body. Where more than one wrap is used, they

should be overlapped so that the front and rear

edges fall flush with the front and rear of the boiler.

Secure wraps in position by using tape or

strapping and buckles. For further details, see

instruction sheet packed with insulation.

Note!

The front and rear insulation pieces will

need to be removed for maintenance of the boiler.

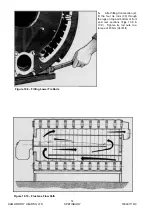

d.

Using a combination of M10 x 35 hex head

bolts, nuts and washers and existing tie rods fit 4

off casing support brackets as shown below.

e.

On SP 110, SP 150 & SP 220 models locate

burner onto mounting plate. On SP 280 and SP 340

models locate burner directly on to boiler front

casting.

f.

Complete all pipework connections and fuel

lines.

g.

Complete installation by fitting casing and

sensors - refer to Section 10.5, 10.6, Fig. 10.13 to

10.21 and Fig. 14.3.

Figure 10.12 - Fitting Casing Support Brackets

Содержание Spetisbury

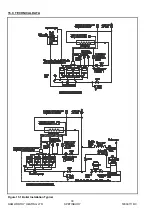

Страница 30: ...HAMWORTHY HEATING LTD 24 SPETISBURY 500001118 C Figure 12 2 Fault Finding Flowchart...

Страница 36: ...HAMWORTHY HEATING LTD 30 SPETISBURY 500001118 C Figure 15 1 Boiler Installation Typical 15 0 TECHNICAL DATA...

Страница 42: ...HAMWORTHY HEATING LTD 36 SPETISBURY 500001118 C NOTES...

Страница 43: ...Notes...