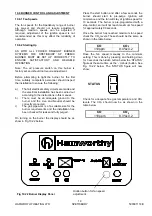

HAMWORTHY HEATING LTD

21

SPETISBURY

500001118/C

11.0 COMMISSIONING AND TESTING

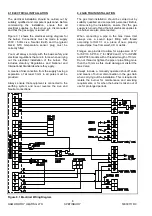

11.1 Electrical Installation

Wiring

MUST

be checked by a suitably competent

person. An isolator correctly fused should be sited close

to the boiler. Refer to section 9 and 10 of this manual.

11.2 Gas Installation

For design see

Section 5: GAS SUPPLY.

The whole of the gas installation including the meter

must be inspected and tested for soundness and

purged in accordance with the recommendations of

IGE/UP/1

or

IGE/UP/1A

as appropriate.

11.3 Water Circulation System

For design see

Section 8: WATER SYSTEM.

The system should be thoroughly flushed out with cold

water without the pump in position. Ensure all the

valves are open.

With the pump fitted the system should be filled and air

locks cleared. Vent the radiators and check for leaks.

If the system is unvented the pressurization unit should

not be utilized for the initial filling. This should be carried

out using a WRC approved double check valve and

temporary filling loop. In order to comply with local

Water Authority Regulations, this loop must be

disconnected when filling is complete. Water treatments

should not be fed through the pressurization unit unless

permitted by the manufacturer. Check the expansion

vessel cushion pressure as detailed by the

manufacturer's Installer's Guide.

11.4 Commissioning The Boiler

Only competent persons registered for working on

non domestic gas appliances should attempt the

following: Before attempting to commission any

boiler, ensure that personnel involved are aware of

what action is about to be taken and begin by

making the following checks:-

1)

Flueway passages to chimney are clear.

2)

Adequate ventilation as per

Section 7: AIR SUPPLY

exists in the boilerhouse.

3)

The system is fully charged with water, ready to

receive heat. All necessary valves are open and the

pump is circulating water.

4)

The pipework and valve arrangement is installed to

Hamworthy Heating recommendations in such a way

that water flow rates will be in accordance with Figure

3.1.

5)

The gas supply pipework is clear of any loose matter,

tested for soundness and purged to

IGE/UP/1

or

IGE/

UP/1A

as appropriate.

11.4.1 Boiler Checks Prior To Lighting

BEFORE

starting the boiler, check the following:

a.

Check that fuel supply is turned off.

b.

Check that electrical supply is isolated.

c.

Check that electrical installation conforms to the

requirements of these Instructions, the IEE Wiring

Regulations for electrical installations, and any other

local Regulations which apply.

d.

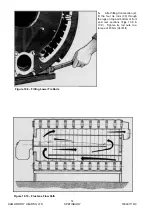

Check boiler castings are undamaged. Remove

access plates to check flue plates are correctly

located in sections, then replace and reseal.

e.

Check all thermostat bulbs are correctly inserted

in the appropriate pockets on the upper and lower

faces of the front casing.

f.

Check for water leaks and ensure that both boiler

and heating system is full of water and properly

vented. On SP 280 and 340 models check

distribution tube is fitted.

g.

Check that all drain cocks are closed, and that all

isolating valves in flow and return pipework are

open.

h.

Check soundness of gas installation and that

pipework is purged of air, as detailed in I. Gas. E.

Publications IGE/UP/1 or IGE/UP/1A respectively.

Check that gas meter is operational and has been

checked by the local region of British Gas.

j.

Check that gas meter and supply pipework is of

sufficient size to meet the input rating of the burner/

boiler. Refer to Figure 15.2.

k.

Check that burner output is correct for size of

boiler in question, referring to Figure 15.7

Note: -

Refer to the firing procedure of the burner in

Section 10.6 of this manual before firing the

boiler.

Always adjust the fuel supply upwards from a

low position to ensure that a fuel rich mixture is

not achieved.

11.4.2 Gas fired Boilers

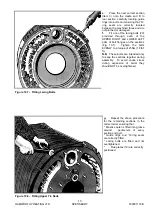

a.

Check that ignition electrode and rectification

probe are correctly positioned. See Fig. 11.2 below;

Figure 11.2 - Spark Gap and Electrode Positions

Содержание Spetisbury

Страница 30: ...HAMWORTHY HEATING LTD 24 SPETISBURY 500001118 C Figure 12 2 Fault Finding Flowchart...

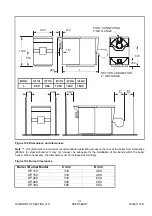

Страница 36: ...HAMWORTHY HEATING LTD 30 SPETISBURY 500001118 C Figure 15 1 Boiler Installation Typical 15 0 TECHNICAL DATA...

Страница 42: ...HAMWORTHY HEATING LTD 36 SPETISBURY 500001118 C NOTES...

Страница 43: ...Notes...