HAMWORTHY HEATING LTD

8

SPETISBURY

500001118/C

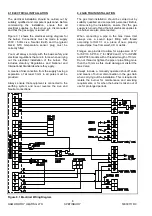

9.1 ELECTRICAL INSTALLATION

The electrical installation should be carried out by

suitably qualified and competent personnel. Before

commencing the installation, ensure that all

electrical supplies to the burner are disconnected

and that the gas supply is turned off.

Figure 9.1 shows the electrical wiring diagram for

the burner. Connections must be made to supply

230V / 50Hz Live, Neutral, Earth and the (green/

black) NTC temperature sensor plug must be

correctly fitted.

You must always comply with the basic safety and

electrical regulations that are in force when carrying

out the electrical installation of the burner. This

includes statutory Regulations and National and

International Standards where they apply.

A means of disconnection from the supply having a

separation of at least 3mm in all poles must be

provided.

Always ensure that equipment is connected to the

earthing system and never reverse the Live and

Neutral connections.

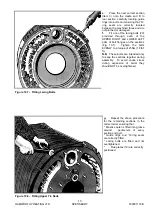

9.2 GAS TRAIN INSTALLATION

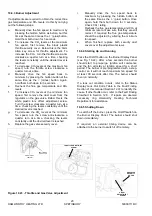

The gas train installation should be carried out by

suitably qualified and competent personnel. Before

commencing the installation, ensure that the gas

supply is turned off and that all electrical supplies to

the burner are also disconnected.

When connecting a pipe to the Gas Valve Inlet

always use a sound taper fitting with thread

according to ISO 7-1 or a piece of new, properly

reamed pipe, free from swarf, dirt or debris.

Flanges are provided to allow for a pipe size of ¾”

for SP110, SP150, 1” for SP220 and 1¼” for SP280

and SP340 models with a threaded length of 13mm.

Do not thread or tighten the pipe or pipe fitting more

than the 13mm as this could damage or distort the

Gas Valve.

Always include a manually operated shut-off valve

and means of burner disconnection in the gas train

when carrying out the installation. This is required to

isolate the burner for maintenance and servicing

requirements, or for when the burner is taken out of

use for prolonged periods.

Figure 9.1 Electrical Wiring Diagram

Содержание Spetisbury

Страница 30: ...HAMWORTHY HEATING LTD 24 SPETISBURY 500001118 C Figure 12 2 Fault Finding Flowchart...

Страница 36: ...HAMWORTHY HEATING LTD 30 SPETISBURY 500001118 C Figure 15 1 Boiler Installation Typical 15 0 TECHNICAL DATA...

Страница 42: ...HAMWORTHY HEATING LTD 36 SPETISBURY 500001118 C NOTES...

Страница 43: ...Notes...