HAMWORTHY HEATING LTD

22

SPETISBURY

500001118/C

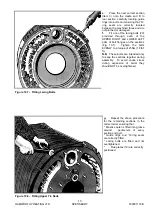

b.

Check burner seats correctly onto burner

mounting plate and is securely fastened in place.

c.

Open main isolating valve in gas supply to boiler.

Check for leaks throughout gas train and pipework

to boiler.

d.

Adjust gas supply governor to achieve at least

17.5 mbar (7.0 in wg) at inlet to boiler gas train.

Ensure that maximum pressure of gas train

governor is not exceeded. If a gas booster is to be

fitted, commission in accordance with the

manufacturer’s instructions.

e.

Close main isolating valve in gas supply and start

the burner. The burner control will first operate the

fan to pre-purge the boiler, then produce an ignition

spark and attempt to ignite the burner. The flame

should fail to ignite and the burner should go to

lockout after three failed ignition attempts.

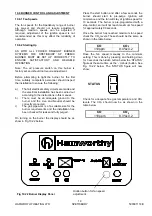

f.

Open main isolating valve in gas supply. Reset

the burner control and restart the burner, the main

flame should light at the ignition rate and stabilise

for 90 seconds before running up to full rate. Note:

the fan speed for start, max/min run is factory set

and does not need adjustment (refer to fig 15.7).

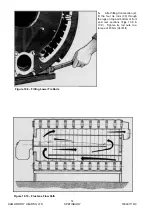

g.

After allowing burner to reach stable firing

conditions for approximately 15 minutes, carry out

combustion gas check.

Measure gas pressure at the burner inlet CO

2

, CO,

flue gas temperature, and circulating water

temperature rise across the boiler. The readings

obtained for the appropriate gas should be as

indicated in figure 11.1, target appliance readings.

Readings should be taken at max and min firing

rates. Check and adjust parameters to comply with

target figures nominated in section 10.6 of this

manual.

IF BURNER REPEATEDLY FAILS TO LIGHT, A

FULL INVESTIGATION TO FIND CAUSE SHOULD

BE MADE.

h.

Check gas flow rate at meter. Ensure that all

other appliances served by the meter are isolated

whilst flow rate is checked.

j.

Cycle boiler on and off several times to ensure

reliable burner ignition and boiler operation. Check

for gas, water and flue gas leakage. Tighten all

access, flue box and burner mounting bolts and

nuts.

k.

Set boiler control thermostat to required setting,

and check operation of heating control system.

l.

Fully familiarise the user with the boiler operating

controls, the main component functions and the

safety features.

THESE INSTALLATION AND SERVICING

INSTRUCTIONS SHOULD BE LEFT WITH THE

USER OF THE BOILER FOR FUTURE

REFERENCE.

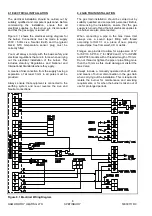

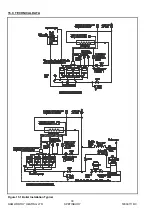

11.5 External Controls

The external controls used in typical boiler

installations, for both vented and unvented systems,

are shown in Figure 15.1. If different systems or

controls are to be used and there are any doubts as

to the suitability, contact Hamworthy Heating

Technical Department for advice.

11.6 Installation Noise

I

n order to avoid the possibility of noise from the

installation, care should be taken to follow the

manufacturer’s instructions. Particular attention should

be paid to minimum water flow rates. If acoustic

insulation is added to the boiler, care must be taken not

to impede combustion or ventilation air flow. If in doubt

contact the manufacturer.

11.7 User Instructions

When the above is complete, the boiler owner or their

representative should be made aware of the lighting

and operating instructions . A practical demonstration

should be given describing each functional step. This

Installer's Guide should then be handed over and kept

in a safe place for easy reference.

Содержание Spetisbury

Страница 30: ...HAMWORTHY HEATING LTD 24 SPETISBURY 500001118 C Figure 12 2 Fault Finding Flowchart...

Страница 36: ...HAMWORTHY HEATING LTD 30 SPETISBURY 500001118 C Figure 15 1 Boiler Installation Typical 15 0 TECHNICAL DATA...

Страница 42: ...HAMWORTHY HEATING LTD 36 SPETISBURY 500001118 C NOTES...

Страница 43: ...Notes...