HAMWORTHY HEATING LTD

3

SPETISBURY

500001118/C

3.0 GENERAL REQUIREMENTS

3.1 Related Documents.

Gas Safety (Installation and Use) Regulations

1994 – (As amended).

It is the law that all gas

appliances are installed by competent persons, in

accordance with the above regulations. Failure to

install appliances correctly could lead to

prosecution.

It is in your own interest, and that of safety, to

ensure that this law is complied with.

The installation of the boiler

MUST

be in accordance

with the relevant requirements of the Gas Safety

Regulations, Building Regulations, I.E.E. Regulations

and the bylaws of the local water undertaking.

The installation should also be in accordance with any

relevant requirements of the local gas region and local

authority and the relevant recommendations of the

following documents :-

British Standards

BS.5854

- Code of practice for flues and flue

structures in buildings. See para 5 (3.6).

BS.6644

- Specification for installation of gas fired

hot water boilers of rated inputs between 60kW and

2MW.

BS.6700

- Design, Installation, testing and

maintenance of services supplying water for

domestic use.

BS.6880

- Code of practice for low temperature hot

water heating systems of output greater than 45kW.

Part 1:

Fundamentals & design considerations.

Part 2:

Selection of equipment.

Part 3:

Installation, commissioning & maintenance.

BS 7074 -

Application, selection and installation of

expansion vessels and ancillary equipment for sealed

water systems.

Part 2:

Code of practice for low and

medium temperature hot water systems.

BS.CP342

- Code of practice for centralised hot

water supply.

Part 2

: Buildings other than individual

dwellings.

I. Gas E. Publications

IGE/UP/1

Soundness testing and purging of

industrial and commercial gas installations.

IGE/UP/1A

Soundness testing and direct purging of

small low pressure industrial and commercial natural

gas installations.

IGE/UP/2

Gas installation pipework, boosters and

compressors in industrial and commercial premises.

IGE/UP/10

Installation of gas appliances in industrial

and commercial premises.

Health and Safety Executive :-

Guidance note PM5

- Automatically controlled steam

and hot water boilers.

CIBSE Publications:-

"CIBSE Guide"

It is impractical in this document to specify all relevant

information, but the following extracts from the above

references are emphasised since failure to comply with

these requirements will almost certainly result in an

unsatisfactory installation.

3.2 Feed Water Quality

If the boiler feed water has a high degree of

hardness, it is recommended that the water be

treated to prevent precipitation of scale or sludge in

the boiler water passageways. Details of additives

can be obtained from any reliable manufacturer of

water treatment products or the local water

authority.

It should be noted however, that even if the boiler water

is of average hardness, not requiring treatment,

subsequent draining of the system for repair or constant

make-up water due to an undetected leak will cause

additional deposits and gradual build-up of scale. It is

essential therefore, that leaks are attended to promptly

and draining is kept to an absolute minimum.

It is recommended that the system be flushed out at

least twice before any water treatment is added. If

any doubt exists regarding the internal cleanliness

of an old system, consideration should be given to

the fitting of a coarse filter in the return pipework to

the boiler(s).

3.3 Adequate Water Flow

Care should be taken in the initial design and layout

having due regard for adequate water flow through the

boilers and the influence of the system controls.

It is recommended that the system design should

ensure a minimum return temperature of 50 °C.

If the temperature/flow rates of the application

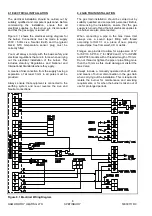

cannot meet those given in Figure 3.1 it may be

necessary to incorporate mixing valves and shunt

pumps to ensure that the boiler will operate

satisfactorily. Figure 3.1 shows recommended and

minimum water flows required with the associated

pressure losses. The control system and valves,

where fitted, should be regulated to avoid lower

flows occurring.

3.4 Time Clock Control

In order to avoid local overheating and progressive

calcium deposition at zero flow conditions where

boilers are operated from time clocks, provision

should be made for a 5 minute circulating pump

over-run after the last boiler has ceased firing.

Содержание Spetisbury

Страница 30: ...HAMWORTHY HEATING LTD 24 SPETISBURY 500001118 C Figure 12 2 Fault Finding Flowchart...

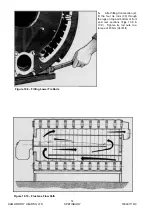

Страница 36: ...HAMWORTHY HEATING LTD 30 SPETISBURY 500001118 C Figure 15 1 Boiler Installation Typical 15 0 TECHNICAL DATA...

Страница 42: ...HAMWORTHY HEATING LTD 36 SPETISBURY 500001118 C NOTES...

Страница 43: ...Notes...