Page

6

SmartFOAM

SAFETY

IMPORTANT!

ALL HALE SMARTFOAM MODELS ELECTRONIC

FOAM PROPORTIONING SYSTEMS ARE DE-

SIGNED FOR OPTIMUM SAFETY OF ITS OPERA-

TORS AND TO PROVIDE RELIABLE AND SAFE

FOAM CONCENTRATE INJECTION. FOR ADDED

PROTECTION AND BEFORE ATTEMPTING INSTAL-

LATION OR OPERATION PLEASE FOLLOW THE

SAFETY GUIDELINES LISTED IN THIS SECTION

AND ADHERE TO ALL WARNING, DANGER, CAU-

TION AND IMPORTANT NOTES FOUND WITHIN

THIS GUIDE.

THIS SECTION ON SAFETY MUST BE CAREFULLY

READ, UNDERSTOOD AND ADHERED TO

STRICTLY BY ALL INSTALLERS AND OPERATORS

BEFORE ATTEMPTING TO INSTALL OR OPERATE

THE SMARTFOAM PROPORTIONING SYSTEM.

INCORPORATE THE WARNINGS AND CAUTIONS

AS WRITTEN WHEN DEVELOPING DEPART-

MENTAL APPARATUS OPERATING PROCEDURES.

SmartFOAM is a trademark of Hale Products, In-

corporated. All other brand and product names are

the trademarks of their respective

holders.

GUIDELINES

READ ALL INSTRUCTIONS THOROUGHLY BEFORE

BEGINNING ANY INSTALLATION OR OPERATION

PROCESS.

❑

Installation should be performed by a trained and

qualified installer, or your authorized Hale Prod-

ucts service representative.

❑

Be sure the installer has sufficient knowledge, ex-

perience and the proper tools before attempting

any installation.

❑

Make sure proper personal protective equipment is

used when operating or servicing apparatus.

❑

A foam tank low level sensor must be utilized to

protect the Hale Foam proportioner from dry run-

ning.

Failure to use a low level sensor with the

Hale Foam system voids warranty.

❑

DO NOT permanently remove or alter any

guard or insulating devices, or attempt to op-

erate the system when these guards are re-

moved.

❑

Make sure all access/service panels and covers

are installed, closed and latched tight, where ap-

plicable.

❑

DO NOT remove or alter any hydraulic or pneu-

matic connections, electrical devices, etc. DO

NOT tamper with or disconnect safety features or

modify protective guards (such as covers or

doors). DO NOT add or remove structural parts.

Doing so voids the warranty.

Any of the above could affect system capacity and/or

safe operation of the system and is a serious safety

violation which could cause personal injury, could

weaken the construction of the system or could affect

safe operation of the SmartFOAM Proportioning Sys-

tem.

WARNING!

NO MODIFICATIONS OR ADDITIONS MAY BE

MADE TO THE SMARTFOAM PORPORTIONING

SYSTEM WITHOUT PRIOR WRITTEN PERMISSION

FROM:

HALE PRODUCTS, INC

607 NW 27

th

Avenue

Ocala, Florida 34475 USA

Telephone: 352-629-5020

FAX: 800-533-3569

❑

All electrical systems have the potential to

cause sparks during service. Take care to elimi-

nate explosive or hazardous environments dur-

ing service and/or repair.

❑

To prevent electrical shock always disconnect the

primary power source before attempting to service

any part of the Hale Foam system.

❑

To prevent system damage or electrical shock

the main power supply wire is the last connec-

tion made to the Hale Foam motor controller.

❑

Release all pressure then drain all concentrate and

water from the system before servicing any of its

component parts.

Содержание MiniCAFS 2.1A

Страница 3: ...Page 2 SmartFOAM NOTES...

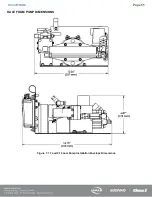

Страница 12: ...Page 11 SmartFOAM HALE FOAM PUMP DIMENSIONS Figure 1 1 7 and 2 1 Foam Pump Installation Envelope Dimensions...

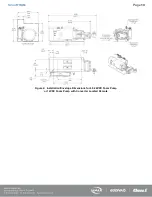

Страница 15: ...Page 14 SmartFOAM Figure 5 Converter Installation Envelope Dimensions Located Remote for 6 5 12VDC Systems...

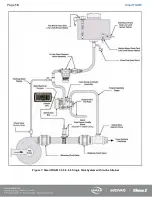

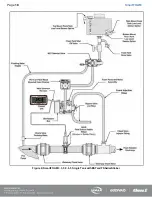

Страница 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

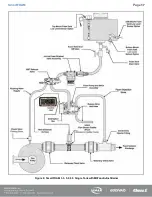

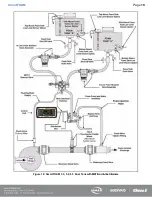

Страница 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

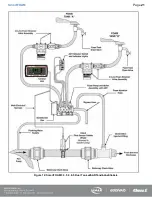

Страница 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Страница 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Страница 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Страница 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Страница 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Страница 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Страница 24: ...Page 23 SmartFOAM Figure 14 SmartFOAM Dual Pump 1 Single Tank with Valve Options and In Line Strainers...

Страница 25: ...Page 24 SmartFOAM Figure 15 SmartFOAM Dual Pump 1 Single Tank System with MST and FS Series Strainers...

Страница 26: ...Page 25 SmartFOAM Figure 16 SmartFOAM Dual Pump 1 Dual Tank System with MDT II and FS Series Strainers...

Страница 27: ...Page 26 SmartFOAM Figure 17 SmartFOAM Dual Pump 2 Single Tank System with valve options and In Line Strainers...

Страница 28: ...Page 27 SmartFOAM Figure 18 SmartFOAM Dual Pump 2 Single Tank System with MST and FS Series Strainers...

Страница 29: ...Page 28 SmartFOAM Figure 19 SmartFOAM Dual Pump 2 Dual Tank System with MDT II and FS Series Strainers...

Страница 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Страница 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Страница 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Страница 77: ...Page 76 SmartFOAM NOTES...

Страница 90: ...89 Page 89 SmartFOAM NOTES...