Page

42

SmartFOAM

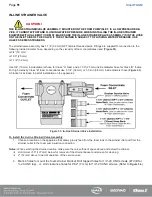

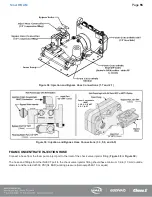

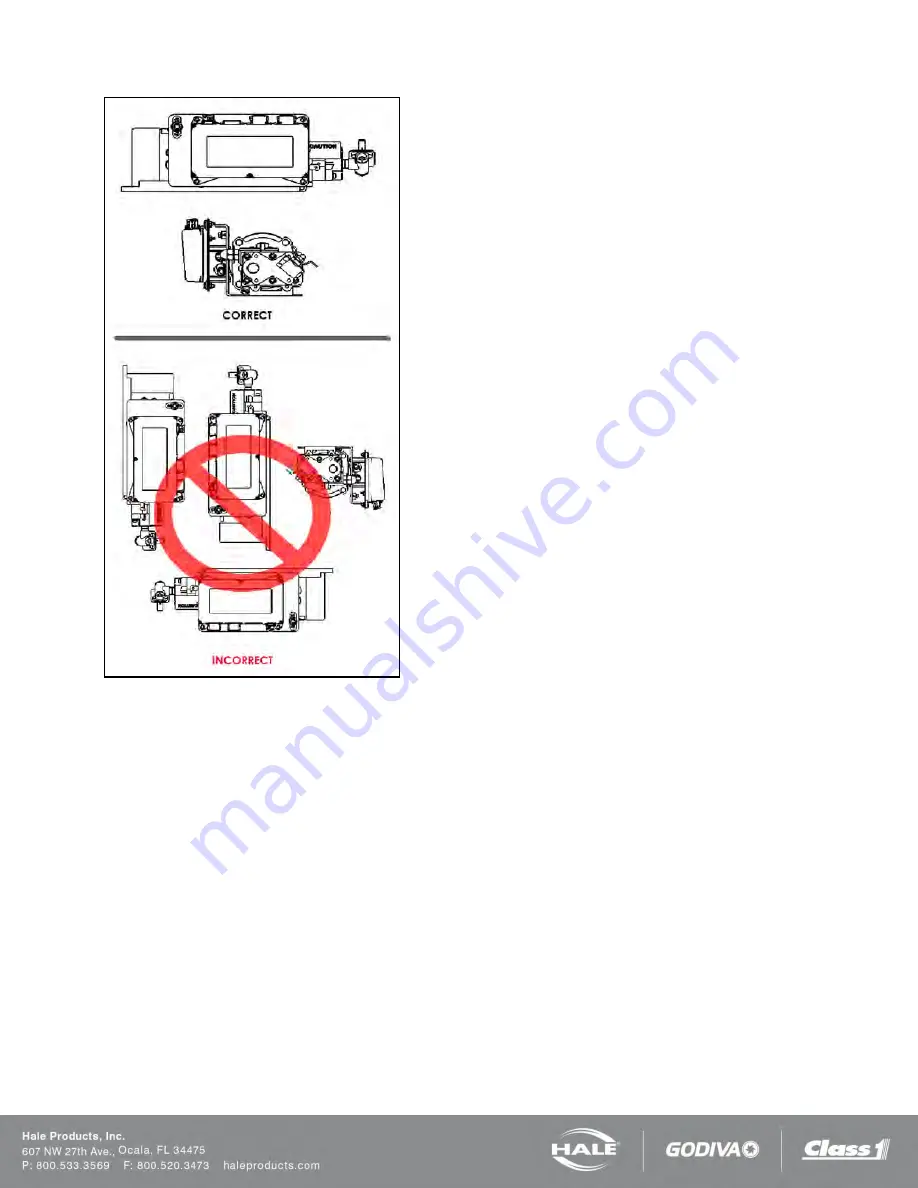

Figure 22: SmartFOAM Gear Pump Installation

Although the system is sealed and designed to be resistant

to the harsh environment of fire-fighting apparatus, a com-

partment with easy operator access is recommended.

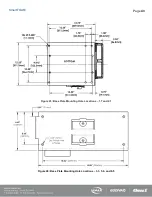

The base plate of the foam pump and motor assembly must

be anchored to a surface or structure that is rigid and of ade-

quate strength to withstand the vibration and stresses of ap-

paratus operation.

The base of the foam pump and motor assembly includes

5/16” (8 mm) diameter predrilled mounting holes. The appa-

ratus mounting location must to be drilled accordingly. The

base plate may be used as a template to mark mounting

hole locations.

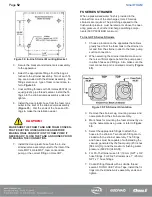

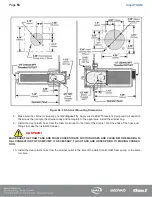

provides the mounting base dimensions for the

SmartFOAM 1.7AHP and 2.1A foam pump and motor as-

sembly.

provides the mounting base dimensions for the

SmartFOAM 3.3, 5.0, and 6.5 foam pump and motor assem-

bly.

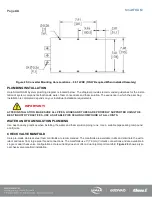

provides the mounting dimensions for the con-

verter for the SmartFOAM 6.5 (12V) system when the con-

verter is mounted separate from the pump and motor as-

sembly.

Make sure the foam concentrate hoses are properly routed

to the inlet and outlet on the foam pump.

Foam concentrate must gravity feed to the foam pump inlet

from the foam tank(s). The foam pump must be mounted in

an area to avoid excessive engine exhaust system heat or

accessory heat build-up.

Содержание MiniCAFS 2.1A

Страница 3: ...Page 2 SmartFOAM NOTES...

Страница 12: ...Page 11 SmartFOAM HALE FOAM PUMP DIMENSIONS Figure 1 1 7 and 2 1 Foam Pump Installation Envelope Dimensions...

Страница 15: ...Page 14 SmartFOAM Figure 5 Converter Installation Envelope Dimensions Located Remote for 6 5 12VDC Systems...

Страница 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Страница 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Страница 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Страница 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Страница 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Страница 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Страница 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Страница 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Страница 24: ...Page 23 SmartFOAM Figure 14 SmartFOAM Dual Pump 1 Single Tank with Valve Options and In Line Strainers...

Страница 25: ...Page 24 SmartFOAM Figure 15 SmartFOAM Dual Pump 1 Single Tank System with MST and FS Series Strainers...

Страница 26: ...Page 25 SmartFOAM Figure 16 SmartFOAM Dual Pump 1 Dual Tank System with MDT II and FS Series Strainers...

Страница 27: ...Page 26 SmartFOAM Figure 17 SmartFOAM Dual Pump 2 Single Tank System with valve options and In Line Strainers...

Страница 28: ...Page 27 SmartFOAM Figure 18 SmartFOAM Dual Pump 2 Single Tank System with MST and FS Series Strainers...

Страница 29: ...Page 28 SmartFOAM Figure 19 SmartFOAM Dual Pump 2 Dual Tank System with MDT II and FS Series Strainers...

Страница 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Страница 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Страница 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Страница 77: ...Page 76 SmartFOAM NOTES...

Страница 90: ...89 Page 89 SmartFOAM NOTES...