Change Drums

To prevent serious burns from dripping material,

never reach under the heated platen after the

platen is out of the drum.

Follow the procedure to change the drum on a fully

heated system.

NOTICE

Be sure to reload the empty supply unit with a full

drum of material immediately. D o not raise the ram

and remove the platen from the empty drum until

you are ready to immediately install a new drum.

Do not raise the ram and remove the platen from

the empty drum unless the supply unit is at full

operating temperature. Drum changes can only be

performed when the system is heated.

An empty drum clamp can interfere with the up

and down operation of the ram. When raising or

lowering the ram, make sure the drum clamp stays

clear of the platen assembly.

Do not use a drum of material that has been

dented or otherwise damaged; damage to the

platen wipers can result.

All systems include Low/Empty Sensors:

• The air will shutoff to prevent the pump from

cavitation. If the light tower kit is installed, a solid

red light indicates that the pail is empty and ready

to change.

• In a tandem system, a flashing red light means

that both drums are empty and the system has

shutdown.

1. Press

to stop material tracking.

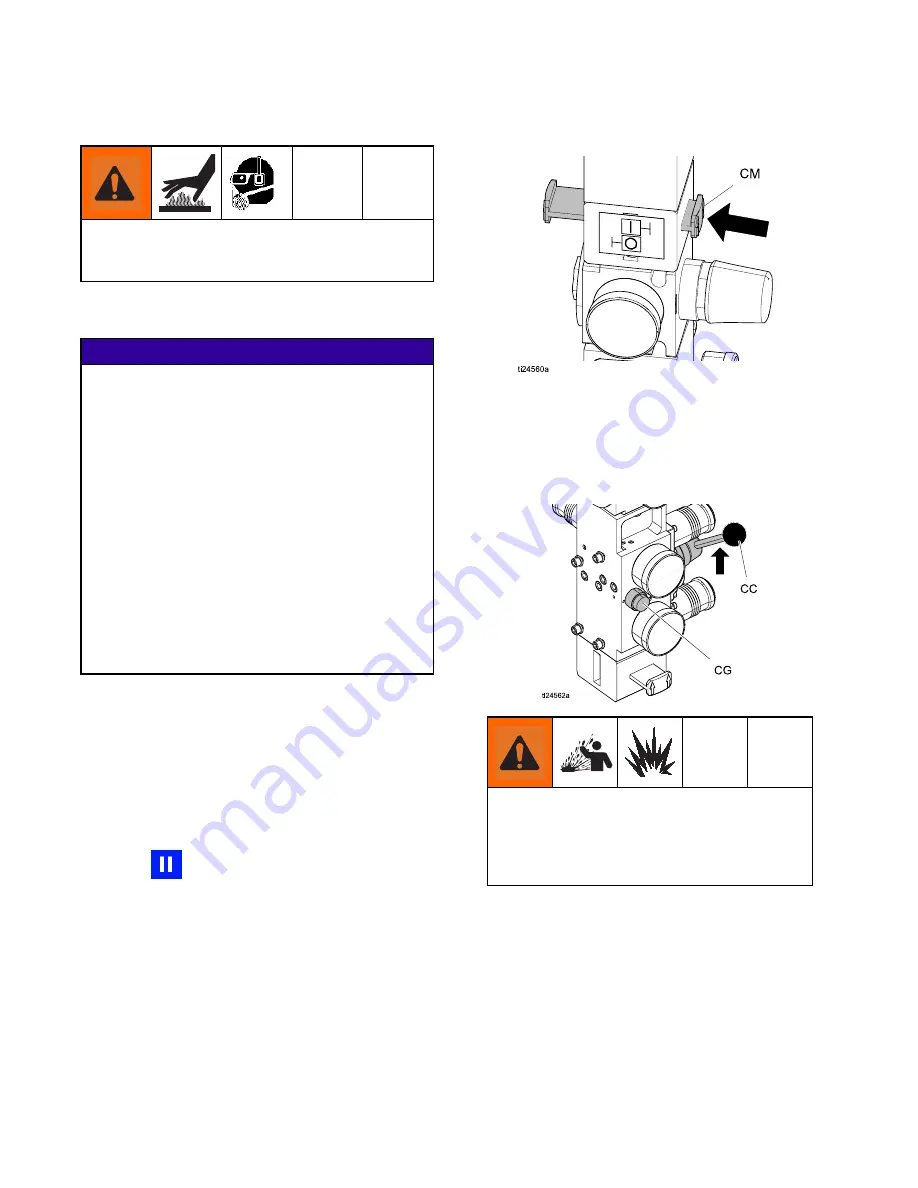

2. Push in the air motor slider valve (CM) to stop

the pump.

3. Set ram director valve (CC) to UP and raise the

platen (G) and immediately press and hold the

blowoff buttons (CG) until the platen is completely

out of the drum. Use minimum amount of air

pressure necessary to push the platen out of the

drum.

Excessive air pressure in the material drum

could cause the drum to rupture, causing

serious injury. The platen must be free to move

out of the drum. Never use drum blowoff air

with a damaged drum.

4. Release the blowoff air button and allow the ram

to rise to its full height.

5. Remove the empty drum.

6. Inspect platen and if necessary, remove any

remaining material or material build-up.

7. Follow steps in

, and

38

334130A

Содержание 334130A

Страница 10: ...Component Identification Electrical Control Enclosure Figure 3 Electrical Enclosure 10 334130A...

Страница 57: ...Repair Figure 35 Inside of Electrical Control Enclosure 334130A 57...

Страница 65: ...Parts Parts Therm O Flow 200 Supply Unit 334130A 65...

Страница 68: ...Parts Electrical Module 68 334130A...

Страница 69: ...Parts 334130A 69...