25

ENGLISH

3.4.2

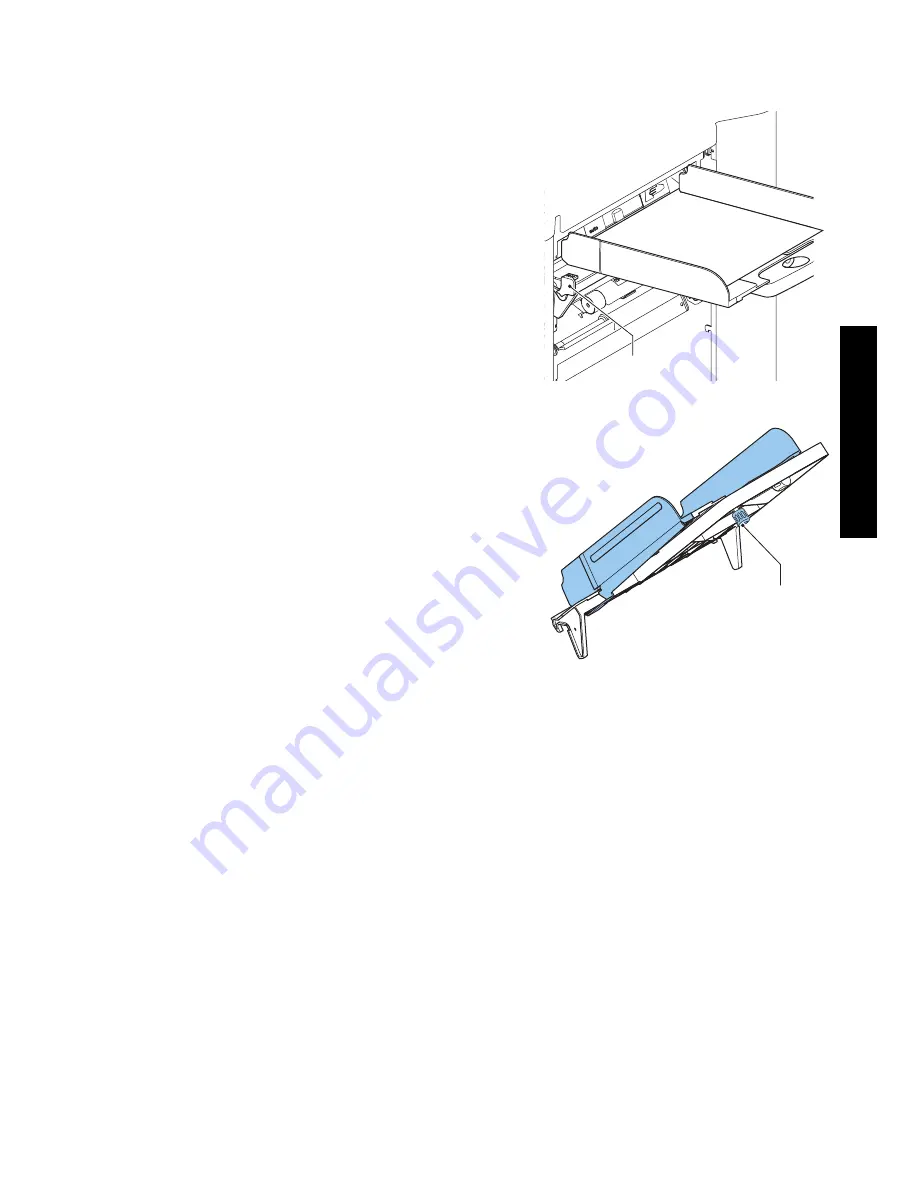

Side Guides

To adjust the side guides it is best to remove the

document feed tray from the feeder as follows:

1. Push handle A downwards.

2. Lift the document feed tray upwards to unhook

it and then pull it out from the feeder.

3. Loosen the knob B half a turn.

4. Grab the side guides in the middle and push

them apart as far as possible.

5. Put a small stack of documents between the side

guides.

6. Grab the side guides in the middle and push

them towards the documents.

The space between the side guides and the

documents should be such that the documents

have just enough play to move freely.

7. Re-tighten knob B.

8. Remove the stack of documents.

9. Replace the document feed tray (3.2.1 ”Document Feed Trays” on page 22).

3.4.3

Document Separation

The term ‘Document separation’ refers to the adjustment required for separating the

upper document from the rest of the documents in the stack. This prevents picking up to

much documents from the stack at the same time.

The document separation for the automatic feeders is set automatically. There are no

manual adjustments needed.

A

B

Содержание 6602 Series

Страница 1: ...6602 Series Inserters OPERATOR MANUAL FIRST EDITION 8 2007...

Страница 6: ...5 ENGLISH Conventions Note A note gives additional relevant information...

Страница 7: ...6...